Computerized Particle Analyzer (CPA)

The W.S. Tyler Computerized Particle Analyzer 4 Conveyor is a dynamic image analysis system designed for particle sizes ranging from 63 microns to 50mm.

All W.S. Tyler CPA units feature real-time function and work with a single line-scan camera; therefore, every particle in the grain size range can be measured and the results used in size and shape analysis. Double detection due to individual images overlapping is ruled out, as are partial ranges and improper measurements of truncated particles. In addition, the real-time function also enables all CPA units to be used as particle counting devices

Each particle at a glance.

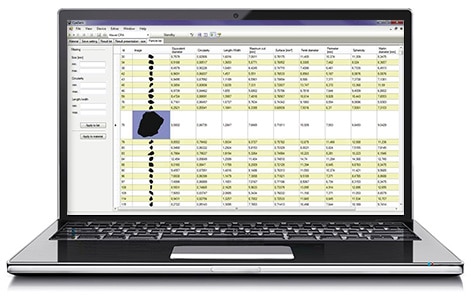

The CpaServ software deployed in the W.S. Tyler CPA systems is easy-to-use, responsive, and runs under most Windows operating systems. Owing to the software, a wide range of particle specifications can be analyzed. The CPA’s individual particle memory allows different grain shape values to be evaluated for every particle measured and statistical means to be determined in freely selectable grain size classes.

Each particle is fully scaled and presented in the particle list. The details regarding particular grain sizes and shapes are stored and can be used for further analyses. Input data errors can be minimized given the software’s ability to cut and paste into documents or tables, such as Excel. Furthermore, multifarious options for filtration enable a customized presentation of results.