Industrial woven wire mesh allows manufacturers to leverage the customization and durability of wire mesh on a large scale. This versatile material features characteristics that benefit countless industries, whether purchasing rolled goods or

cut-to-size pieces.

This ultimate guide was designed to educate you on everything you need to know about industrial woven wire mesh and help distinguish if it's right for you.

Fill out the form for a downloadable PDF version of the guide you can reference later. (Don't forget, you can keep scrolling to read without giving us your email!)

Looking for something specific? Use the buttons below to be directed to a particular subject.

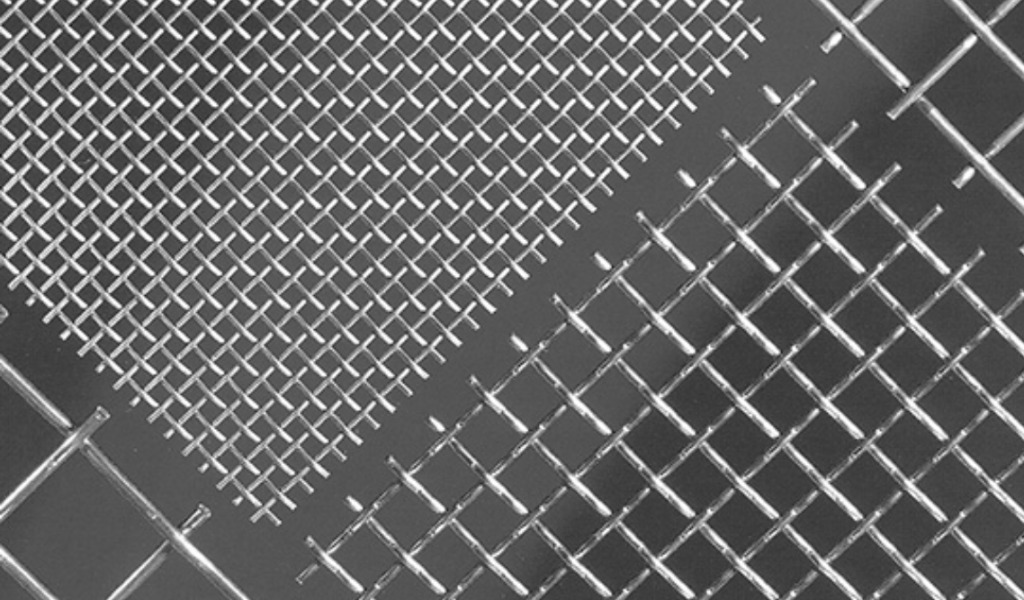

Industrial woven wire mesh, also referred to as industrial metal mesh, is defined as a network of wires that are interlocked together to form precise mesh opening after being woven during a stringent weaving process. To ensure maximum performance is achieved, all aspects of the mesh’s profile, including the weave pattern, wire diameter, opening size, and post-weaving processes, are methodically planned out before setting up the weaving loom.

Now, industrial woven wire mesh can be constructed from various metallic alloys. While 304 and 316 stainless steel stand as the most widely used alloy, you can also employ other alloys such as nickel, Hastelloy, and titanium.

To that end, what separates industrial wire mesh from other woven wire mesh solutions is that industrial mesh is produced as rolled goods or cut-to-size pieces.

Industrial wire mesh rolls are generally woven to a standard length of 100ft. That said, you can acquire rolls at half-lengths of either 12.5m or 15m.

Regardless if you purchase full-length or half-length rolls, it should be noted that a +/- 10% variation in length can be expected.

If you require mesh pieces that fall outside the parameter of a standard mesh roll, cut-to-size pieces can be purchased. When requesting cut-to-size pieces, all parameters of the mesh must be provided.

This includes the quantity, size, length, width, angles, and ratio of all pieces.

Compared to similar materials (discussed below), industrial stands out as it can deliver a more broad offering of pore openings sizes. Wire mesh can be woven to a specification of 4” to 20 microns (635 mesh) without sacrificing performance.

Another substantial advantage industrial woven wire mesh has over other materials is its ability to be woven into several weave patterns that deliver a specific level of accuracy and flow rate. This makes it easier for you to accommodate your filtration and screening requirements.

While every weave may seem the same, industrial woven wire mesh comes in a variety of weave patterns. That said, these patterns can be classified into two categories: square mesh and filter cloth.

Square mesh is identifiable as a woven wire mesh variant that employs warp and weft of equivalent wire diameter. With plain weave, inter-crimped weave, and pre-crimped weave profiles to choose from, square mesh can utilize thicker wires than more complex weave patterns.

As a result, square mesh delivers a high level of durability.

Square Mesh Weave Pattern:

Plain Weave

Twilled Weave, 4-bonded

Twilled Weave,5-bonded, EGLA 5, Stain Twilled Weave

Double Intermediate Crimp Screen, Type C

Lock Crimp Screen, Type D

Flat Top Screen, Type E

Pressure Welded Screen, Type F

Filter cloth is a woven wire mesh variant specifically designed to deliver optimal flow rate, cut point, durability, and cleanability when attempting to obstruct finer particles. Compared to other filter media, such as metal fiber felt and perforated plate, woven wire filter cloth is one of the most versatile with the ability to rid contaminants or extract a filter cake.

Now, filter cloth can either be two-dimensional or three-dimensional.

Two-dimensional filter cloth entails the traditional, flat plain-woven wire mesh filters that have been used in the past. Because of their flat, linear profile, two-dimensional filter cloth has a limited filtration surface area.

A three-Dimensional filter cloth is a woven wire mesh filter that essentially stacks two layers of two-dimensional mesh filters and offsetting them. As a result, you are left with a mesh filter that consists of double the amount of filtration surface area, which, in turn, doubles the flow rate and efficiency of the filter system it is placed in.

Filter Cloth Weave Pattern:

SPW – Single Plain Dutch Weave

The SPW single plain Dutch filter cloth weave pattern features reduced spacing between the weft wires throughout the mesh. As a result, the mesh has increased durability with five times the amount of weft wires than warp wires.

DTW-S – Dutch Twilled Weave

The DTW-S Dutch twilled weave pattern employs a 2/2 twilled weave that traditionally involves positioning the weft wires closely. To facilitate the close weft wire placement without impacting throughput, this particular weave pattern uses thinner wires in the weft direction.

RPD-S – Reverse Plain Dutch Weave

The RPD-S reverse plain Dutch weave pattern applies reverse wire diameter parameters to a plain weave. The entails using warp wires that are thinner than the weft wires to position the warp wires closely together, delivering adequate durability and throughput.

TRD-S – Twilled Reverse Dutch Weave

The TRD-S Twilled reverse Dutch weave pattern is an identical weave to a reverse plain Dutch weave. The most significant difference is that this weave pattern utilizes a 2/2 twilled weave.

You are left with a filter cloth that does not distort as much in the warp direction when compared to a plain weave.

BMT/BMT-ZZ-S – Broad Mesh Twilled Dutch Weave

The Broad Mesh Twilled Dutch Weave consist of an innovative 2/2 weave that features weft wires that are more spaced out than other filter cloth weave patterns. This helps works to increase the amount of achievable filtration surface area.

You can also apply a unique zigzag pattern if you desire a filter cloth that has increased stability and throughput.

RPD HIFLO-S – High-Performance Weave

The RPD HIFLO-S weave pattern is a state-of-the-art three dimensional weave pattern that offsets two layers reverse diameter plain weave filter cloth. Because these two layers are essentially stacked on top of one another, both the filtration surface area and amount of pore openings are doubled.

To that end, the amount of stability, flowrate, and accuracy that RPD HIFLO-S delivers has yet to be achieved by a two-dimensional weave pattern.

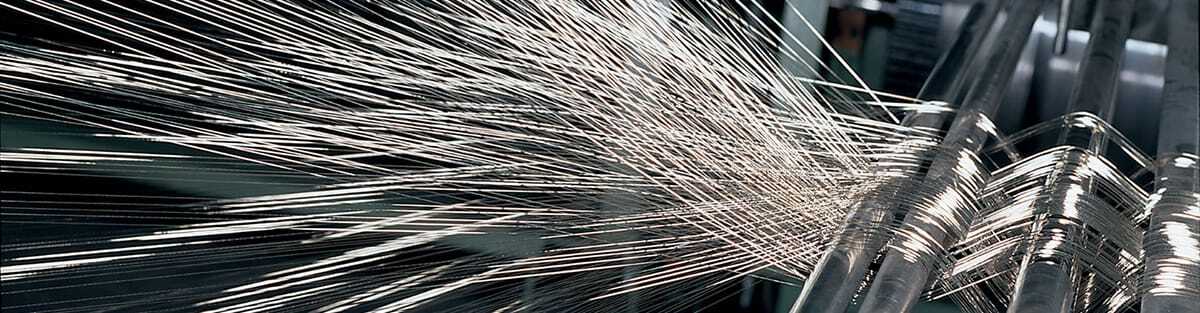

To facilitate the centuries-old weaving process, wire mesh suppliers must employ specialized weaving looms designed to work with metallic wires. These looms consist of seven components: a warp beam, warp wires, heddle frames, weft wires, a rapier band, a reed, and a front take-up mechanism.

To initiate the weaving process, a loom operator will attach and arrange the individual wires on the warp according to their position in the weave. To prevent entanglement, these wires are housed in a wire housing unit known as a creel.

Once attached, the warp beam is wound, allowing the proper length of wire to be wrapped around the beam.

Each wire wound on the warp beam is threaded through its own heddle in a specific heddle frame then carefully threaded through the reed openings based on their order in the weave. At this point, the warp beam, heddle frame assembly are transferred to the weaving hall, and the remainder of the loom is assembled.

NOTE: A great deal of attention to detail must be applied when threading the wire through the heddle frames and reed, as this process control how accurate the mesh specifications are.

Once the loom is fully assembled and the wires are properly threaded, the weaving process can begin.

When first initializing the weaving loom, the warp beam unwinds slightly to feed a small increment of wires. At the same time, the front take-up mechanism winds the same increment of wires to maintain the required tension to produce high-quality mesh.

Once these movements are made in conjunction, the heddle frames shift to separate the wires. In a two-heddle frame system, the first heddle frame lifts one half of the wires, and the second heddle frame drives the other half of wires down.

While the two sets of wires are separated, a weft wire, typically fed from a wire spool that is separated from the creel and placed next to the loom, is shot between the wires by the rapier band. The rapier band then moves back to its resting position.

It's at this point that the reed propels the weft wire to its final position, creating the precise cross-sections that wire mesh is known for. Once the weft wire is positioned, the reed returns to its resting position.

This marks the completion of the first interval.

To continue the weaving process, the warp beam and front take-up mechanism make the same slight, rotating movement to begin another interval. At the same time, the heddle frames will switch potion, wedging the previous weft wire as the two sets of wires are separated in the opposite direction.

These joint movements repeatedly continue until the desired length and mesh specification is woven.

We have established that industrial woven wire mesh provides optimal screening and filtration to various applications. To confidently identify woven wire mesh as the best possible solution, you must gain insight into the other media types that provide similar functions.

Welded wire mesh features similar square openings seen in square woven wire mesh; however, the individual wires are held together after being welded at each intersection rather than being interlocked together. This is generally done using a TIG weld or spot weld, which helps create pore openings that are far more permanent and rigid.

To that end, welded wire mesh is limited when creating finer mesh openings because of how the mesh reacts to the welding process.

Wedge Wire is a screening media constructed from several v-shaped wires arranged and welded onto a supportive structure. The slotted profile of the welded wires allows for optimal filtration that delivers desirable flowrate, cleanability, plug resistance, and durability.

Perforated plate is pieces of sheet metal with several openings punched out according to the particles you are working with. This particular media is known for its durability when screening out large, coarse particles.

Expanded wire starts as sheet metal, much like a perforated plate. However, instead of openings being punched out, several slots are cut into the metal, and the metal is stretched, creating spaces at every slotted area.

Again, because expanded wire is initially sheet metal, it is far more durable than wire mesh. Considering its limitations when creating fine pore openings, expanded wire mesh is ideal when screening/filtering large abrasive materials.

Industrial wire mesh is constructed from various alloys such as stainless steel, Hastelloy, and nickel. That said, stainless steel is undoubtedly the most widely used.

Stainless steel delivers the perfect balance of heat resistance, corrosion resistance, overall durability in high-impact applications, and cost-effectiveness. While there are various stainless steel variants, industrial wire mesh is generally woven from 300-series or 400-series wires.

Now, there are several stainless steel variants on the market, all with their own chemical makeup. That said, mesh filters ultimately fall within either 300 series or 400 series.

300 series stainless steel is classified by the amount of nickel and chromium that makes up the alloy and encompasses nine variants: 304, 309, 310, 316, 317, 318, 321, 330, and 347. Of the nine, W.S. Tyler primarily uses 304 and 316 stainless steel, as the other makeups are used for specialized applications.

Now, when it comes to chemical composition, 304 stainless steel is made up of 18% chromium, 8% nickel, and no parts molybdenum. 316 stainless steel, on the other hand, is made up of 16% chromium, 10% nickel, and 2% molybdenum.

Read "304 vs. 316 Stainless Steel Wire Mesh: Which Alloy Should I Use?" for a more in-depth breakdown of the two 300 series variants.

When working with 400 series stainless steel, W.S. Tyler generally uses 430 stainless steel. This particular 400 series variant has a chemical makeup of 11% chromium and 1% manganese.

It's important to note that all 400-series stainless steel alloys generally have an increased amount of carbon compared to 300-series stainless, which makes them more durable.

Additionally, the 400 series is an excellent option for applications that require a mesh that has magnetic capabilities.

While the alloy you select for your woven wire depends on the needs of your process, you will want to be mindful of dissimilar metal corrosion. This is especially true when multiple alloy variants are present in your system.

Dissimilar metal corrosion, often referred to as galvanic corrosion, occurs when two different alloys touch and create an electrochemical reaction. Initiated when moisture or corrosive elements are present in the atmosphere, dissimilar metal corrosion accelerates the rate at which woven wire mesh is corroded.

The resulting effect is a woven wire weave that has compromised structural integrity, compromised accuracy, inconsistent conductivity, and a shorter lifespan.

If you look closely at tour mesh and equipment, dissimilar metal corrosion can detected most of the time. Things you should look out for include:

While dissimilar metal corrosion may seem unavoidable, it is important to know how to prevent it. You should use the following best practices:

As stated above, woven wire mesh filters can be applied to a wide range of filtration applications. That said, to ensure your mesh filter best accommodates your needs, several value-added services are incorporated during the fabrication process after the mesh has been woven.

Industrial wire mesh is often purchased by manufacturers that handle the forming and fabrication of wire mesh components in-house. To make this process easier and ensure the mesh maintains its shape, the mesh should either be annealed or sintered.

Annealing involves the mesh being heated to reduce the internal stress and overall hardness of each wire. As a result, the wires are softer and more malleable, making it the ideal heat treatment for mesh that will be formed into various shapes.

Sintering involves heating the mesh to just below its melting point while simultaneously applying tremendous amounts of pressure to the mesh. This helps to create a more permanent bond at the cross-sections of the mesh, making it the ideal heat treatment method when mesh opening accuracy is vital.

Read "Annealing vs. Sintering Wire Mesh: Which Is Best for Me?" to learn more about heat treating your wire mesh filters.

Some applications require the use of material free of loose debris that would hinder the ability to render desirable results. Ultrasonic cleaning can be applied to remove dust, lint, oils, and other forms of unwanted debris.

During an ultrasonic cleaning, the mesh is placed in a unique solution and subjected to high-frequency vibrations that heat the solution and shake off debris. As a result, you're left with pristine wire mesh.

Calendering is a process in which the mesh is rolled through a machine while being subjected to a tremendous amount of pressure and heat. In turn, the knuckles of the wire mesh cross-sections are flattened, leaving you with a smoother, more stable mesh.

When it comes to the overall cost of industrial woven wire mesh, several factors should be considered. Mesh size, opening size, wire diameter, and weave pattern all affect wire mesh pricing.

Additionally, post-weaving processes such as heat treatment, ultrasonic cleaning, welding, pleating, and calendaring affect the cost of wire mesh as well. Special requests, such as DFARS compliance, are also known to add expenses.

To that end, square mesh weave patterns are typically less expensive than filter cloth weave patterns. This is because filter cloth weave patterns tend to be more complex, thus requiring more labor and attention to detail to weave.

To initiate the industrial mesh buying process, you should reach out and supply the required mesh specification. This includes the length (rolled goods), dimensions (cut-to-size pieces), opening size, wire diameter, and weave pattern.

While you may not know every specification you need, the more information you supply, the better we will be able to identify if your order fits our scope of work and calculate the logistics required to produce the mesh. Additionally, if you can supply samples of the wire mesh specification you wish to purchase, it can be reverse-engineered and recreated.

You should also provide information that accurately illustrates how the mesh will be used. This allows us to properly understand your needs and deliver a solution that resolves your concerns.

After reviewing your specifications with our engineering team, a quote reflecting all aspects of the order will be sent. If you accept the quote, the final step will be to submit a purchase order.

It's at this point that your mesh will begin being fabricated, with order confirmations, tracking numbers, and fabrication updates being sent to you.

The way in which woven wire mesh is packaged will vary depending on the manufacturer. That said, rolls and cut-to-size pieces are most often shipped in custom pallets.

With rolls in particular, lengths of 25 or 30 meters, with half lengths of 12.5 or 15 meters are standard. NOTE: These standard lengths are expected to fall within +/- 10% of the invoiced length.

It is important to remember that partial lengths are available. But a roll cannot consist of three pieces, and each roll must reach at least 2.5 meters.

The width of the roll must be greater than the nominal width, up to 2%.

Cut-to-size pieces, of course, are made to order based on the sides, lengths, radi, and angles set by the customer. Regardless of the form factor, woven wire will arrive with a label containing the following information:

When your woven wire order arrives at your facility, you should, in most cases, also receive the associated inspection documentation. Based on the amount of testing you mesh underwent, you can expect:

Statement of Compliance: Confirms that your mesh adheres to international standards.

Inspection Certification: Verification of the average aperture profile of the weave. (Must be requested)

Chemical Analysis: Breakdown of the chemical composition of the wires of the mesh. Documentation on the specific wire melt will be provided if the mesh itself isn't tested.

Testing Report: Quality control documentation that verifies international standard compliance.

Additional Test Documentation: Documentation that highlights any other miscellaneous testing techniques applied to your mesh.

As industrial woven wire mesh allows manufacturers to buy mesh in large quantities and form the mesh themselves to ensure it fits their needs, it is perfect for several automotive applications.

A popular use for in-house wire mesh fabrication is transmission filters that prevent extraneous material from entering and damaging the various moving parts. Wire mesh is particularly useful as its metallic composition allows it to withstand extreme conditions such as harsh temperatures and tremendous pressure.

Another popular application in recent years is interior design mesh. Wire mesh allows car manufacturers to furnish car interiors with awe-inspiring, semi-transparent design elements that compliment lustrious trimming, eye-catching illumination systems, and protective enclosers.

Read "Woven Wire Mesh in the Automotive Industry" for more insight into how wire mesh benefits the automotive industry.

From the fuel powering the jet engines to the air circulating through the cabin, there are several elements to aviation that can benefit from wire mesh. As it delivers optimal precision and customization, industrial woven wire mesh rolls are often used to fabricate custom filter elements to purify fuel and even the circulating air.

In addition to purification, manufacturers within the aviation and aerospace industry employ wire mesh when fabricating protective components. Wire mesh provides the durability needed to protect various parts of an aircraft, such as the engines and the internal control systems while minimizing the heavyweight that is often associated with other materials like perforated plate.

From an aesthetic perspective, industrial wire mesh can also serve as a design material. This is because the wire mesh can achieve a three-dimensional look that creates a one-of-a-kind experience while also working to absorb the noises from the engines and passengers.

Woven wire mesh features excellent heat resistance and accuracy characteristics that make it ideal for filtering out unwanted contaminants from molten polymers. The customization capabilities of industrial wire mesh allow you to implement pore openings tailored to the known contaminant particle size, reducing the chance of faults and product failure without reducing the throughput of your extruder system.

Now, there are two ways in which you can implement industrial wire mesh during plastic extrusion.

You can either order bulk stripes of wire mesh that are cut to accommodate a continuous belt changer. You can also purchase several large rolls of mesh and use them to assemble screen packs that fit a slide plate changer or a hydraulic piston changer.

Read "The Benefits of Extruder Screens In Plastic Extrusion (With Video)" for more insight into how wire mesh benefits the plastic extrusion process.

Industrial woven wire mesh delivers the customization and versatility to accommodate the needs of countless industries at a large scale. Manufacturers can leverage industrial wire mesh characteristics to achieve optimal results, whether you implement cut strips of mesh for plastic extrusion or buy mesh in bulk to fabricate automotive design elements in-house.

Now, you may have further questions regarding how industrial woven wire mesh can accommodate your specific operation or may be ready to begin implementing it. Regardless, the next step is to fill out the following form to be put in touch with one of our wire mesh experts.

Here at W.S. Tyler, we strive to go beyond simply being a wire mesh supplier and become an extension of your team.