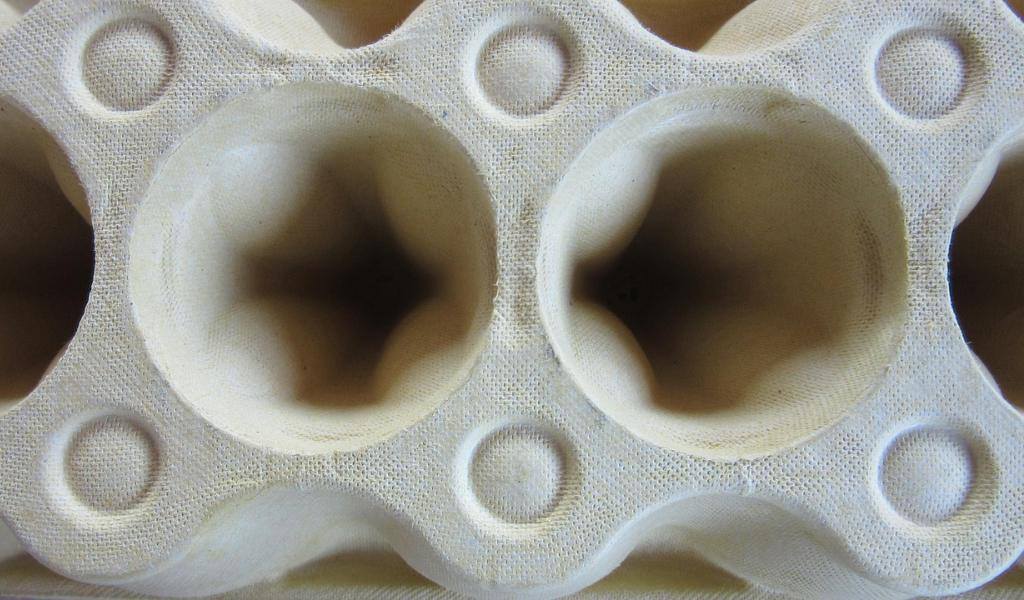

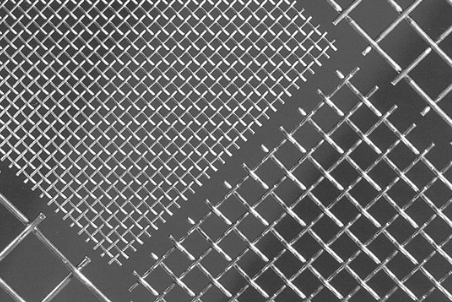

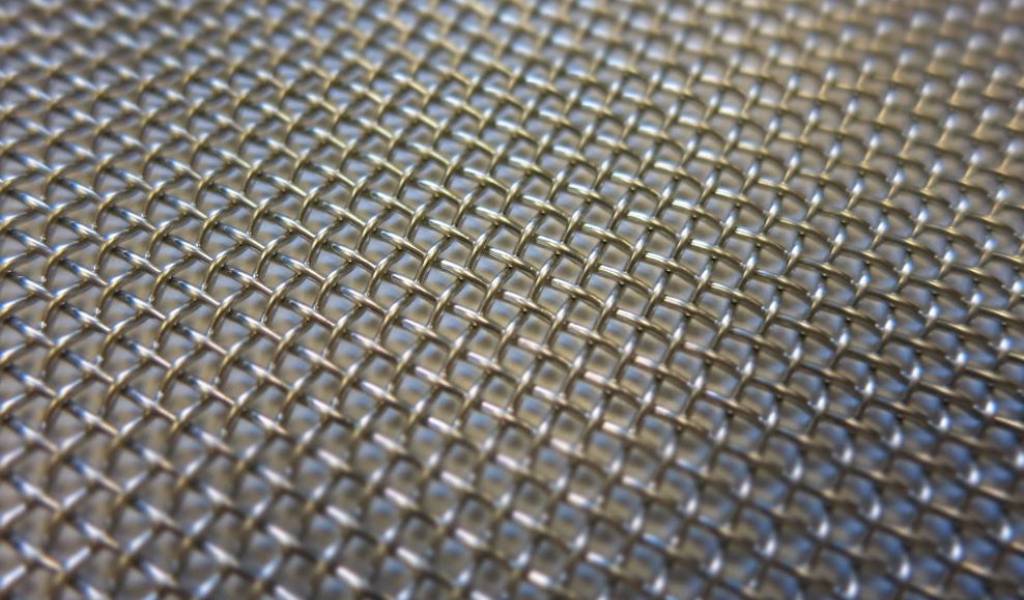

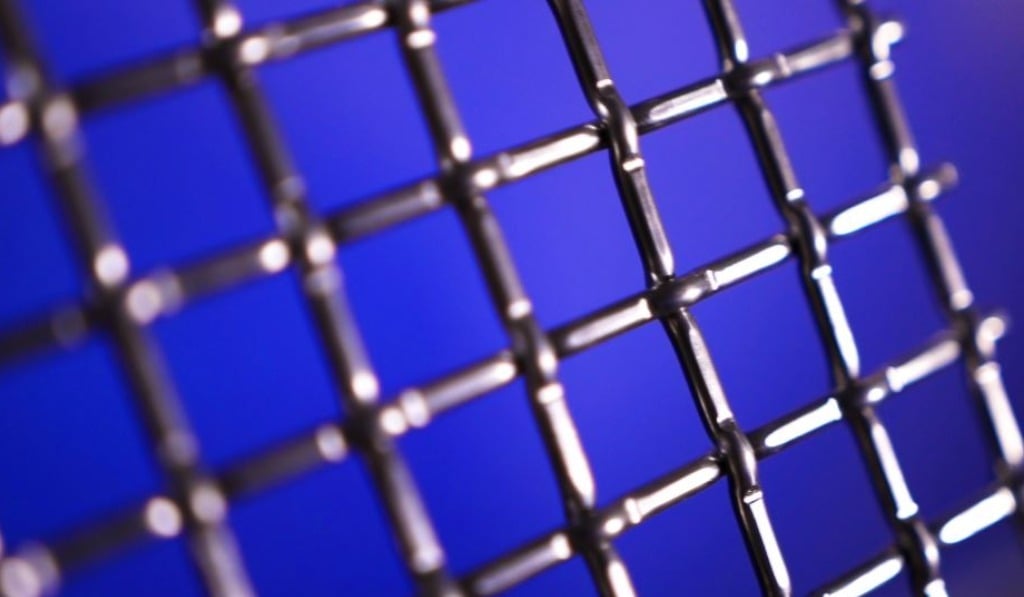

Wire mesh improves efficiency in pulp and fiber operations by optimizing key stages of the forming and drying process. Its uniform structure promotes faster, more consistent water drainage, which shortens cycle times and boosts overall throughput. At the same time, it helps retain and evenly distribute fibers, reducing defects like thin spots, clumping, or uneven surfaces in the final product.

Beyond performance, high-quality wire mesh enhances durability under constant exposure to moisture and heat, reducing the need for frequent replacements and minimizing downtime. The result is a more reliable, cost-effective process that delivers consistent, high-quality molded pulp or fiber-based materials with fewer interruptions.