Flow Fuels the Future

Behind every efficient hydrogen system is a filter designed to balance pressure drop and flow rate. Discover how this balance drives purity, saves energy, and extends service life.

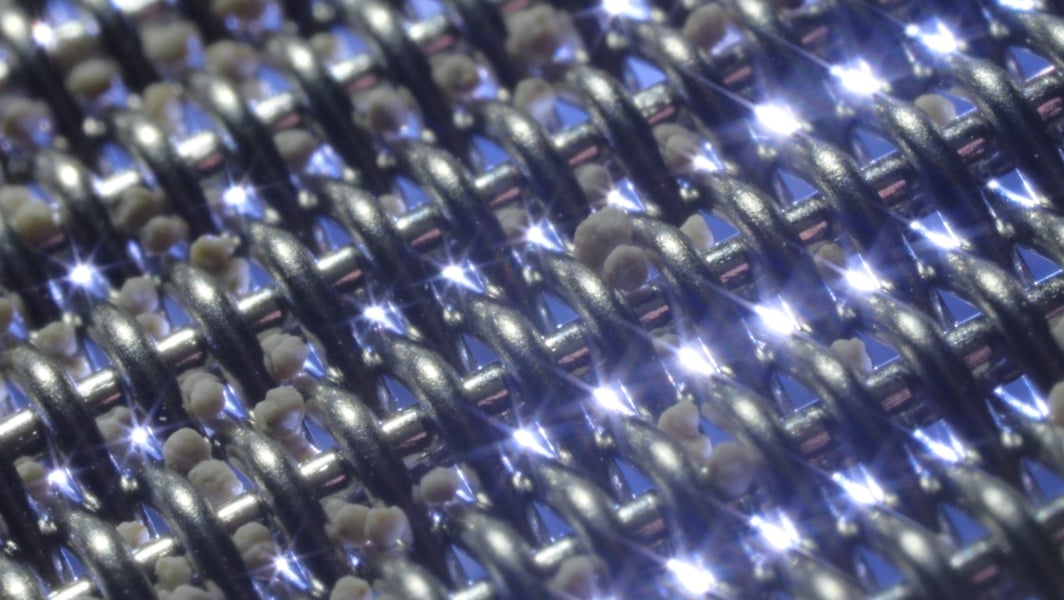

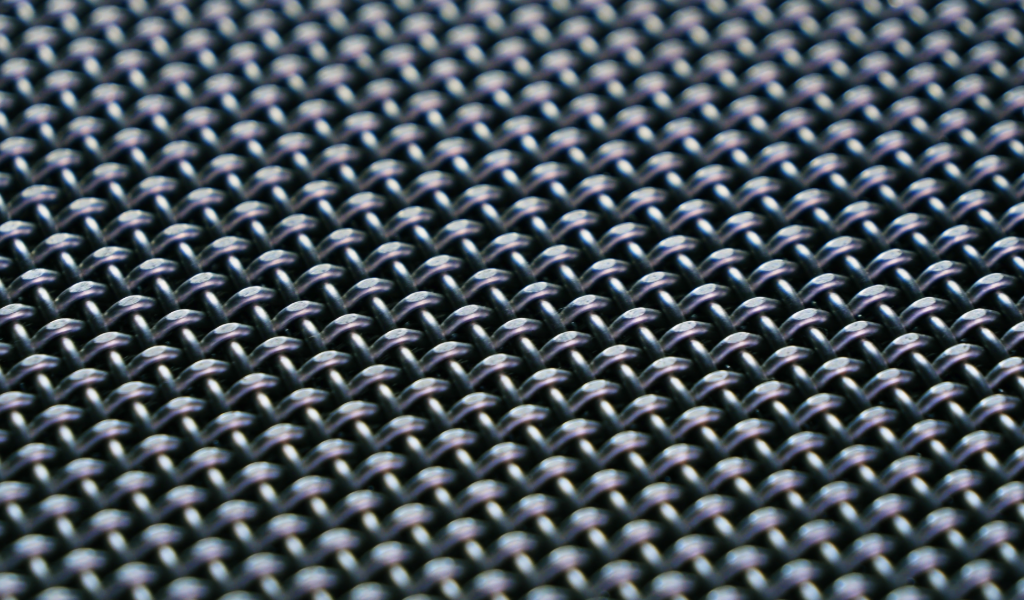

In hydrogen technologies, whether PEM or alkaline electrolysis, fuel cells, or hydrogen storage, precision-engineered woven wire mesh delivers the stability, efficiency, and safety your process demands. As gas diffusion layers, membrane supports, and filtration media, it ensures consistent flow, prevents blockages, and protects critical components from contamination.

In water electrolysis, woven wire mesh optimizes gas separation an d supports membranes under demanding conditions, maximizing efficiency and durability. Its strength, corrosion resistance, and customizability provide long-term reliability and precise performance.

Integrating woven wire mesh into your hydrogen systems delivers proven results, reduced maintenance, and the confidence your operation is built for peak performance.

W.S. Tyler delivers woven wire mesh solutions designed to fit your exact needs , whether in full rolls, durable filter cloth, or precision cut-to-size pieces. Engineered for strength, consistency, and adaptability, our mesh supports a wide range of processes, from filtration and separation to screening and beyond. With uniform openings and reliable performance, you can count on W.S. Tyler wire mesh to provide the foundation for accurate, repeatable results across industries.

In PEM and alkaline electrolysis, fuel cells, and hydrogen storage, precision-engineered woven wire mesh delivers efficiency, stability, and safety. As gas diffusion layers, filtration media, and membrane supports, it ensures consistent flow, blocks contaminants, and protects critical components.

In water electrolysis, our custom mesh optimizes gas separation, strengthens membranes, and boosts durability, essential for producing high-purity green hydrogen. Built from corrosion-resistant alloys and tailored to your needs, W.S. Tyler mesh cuts maintenance, extends equipment life, and keeps your hydrogen systems performing at their best.

High-Pressure Filtration

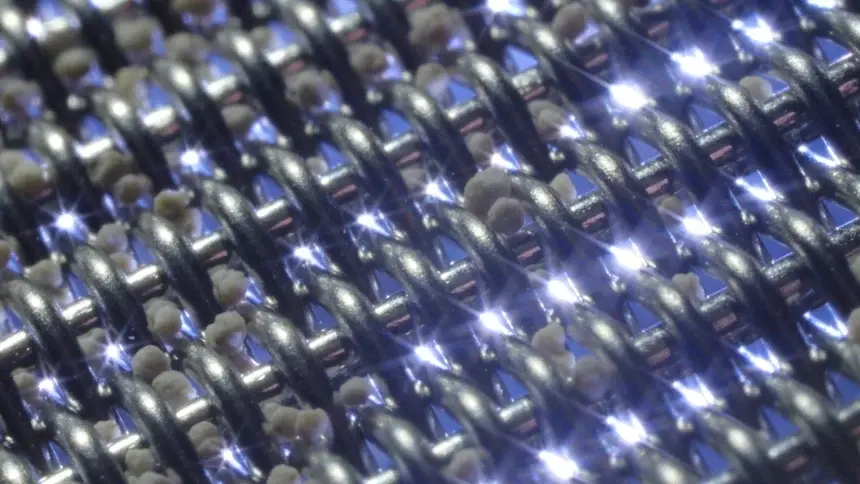

Built to withstand pressures up to 900 bar, POROSTAR® sintered multi-layer mesh laminates provide highly efficient particle filtration, capturing contaminants as small as 5 µm. This protects critical components from wear, fouling, and blockages. Custom layer designs and precise manufacturing techniques, such as laser welding, deliver consistent flow, low pressure drop, and exceptional mechanical strength, even in the harshest operating environments.

Gas Filtration

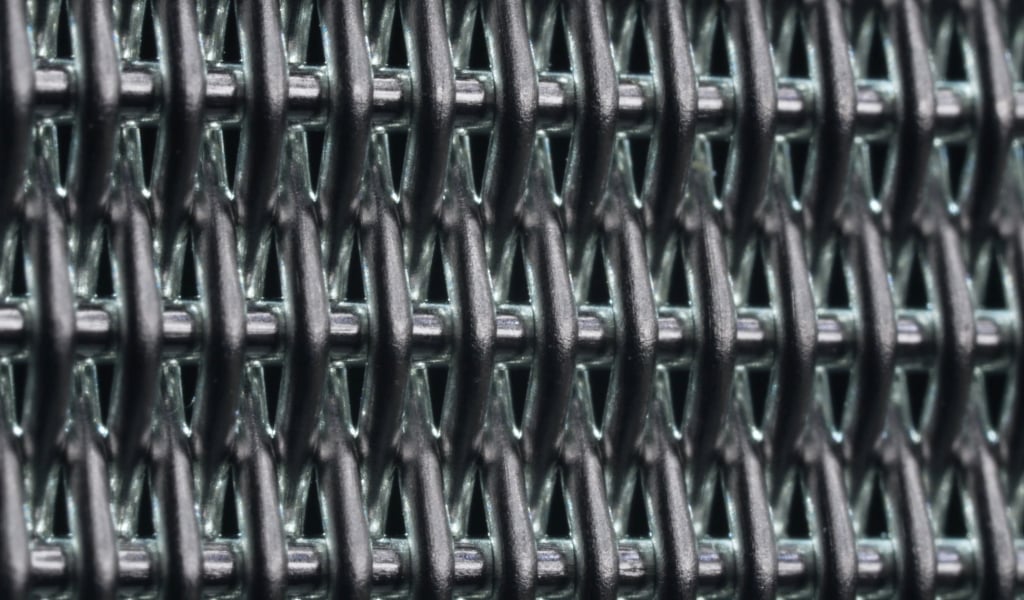

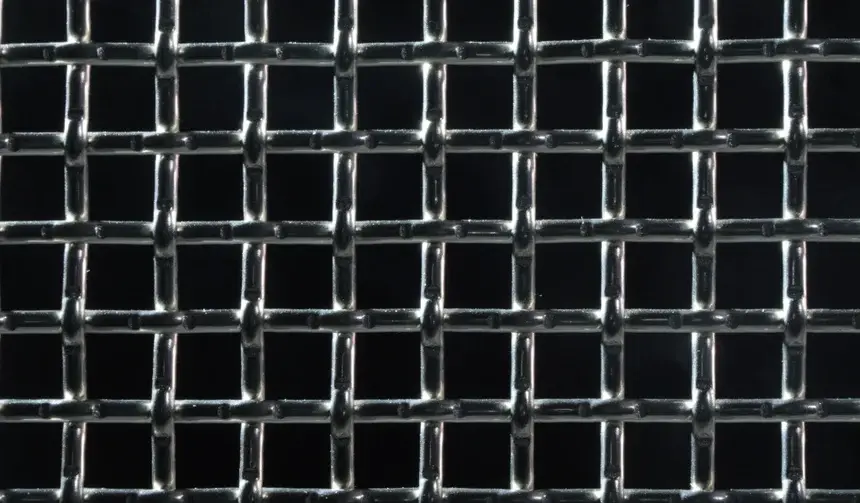

Our wire mesh gas filters remove fine particles at pressures up to 50 bar, protecting PEM electrolysers and other hydrogen equipment. As the porous transport layer (PTL), the mesh ensures consistent water delivery to the MEA, uniform gas flow, and efficient oxygen removal. Precision-moulded or pleated designs maximize flow and minimize pressure drop, while advanced forming and welding ensure a perfect fit and long-lasting performance.

Coolant Filtration

The coolant in fuel cell systems moves through slim pathways between

bipolar plates, where particles can quickly cause blockages and harm the stack. Fine-pored wire mesh captures these impurities, keeping flow paths clear and performance stable. Plastic-injected designs add manufacturing efficiency and consistent quality, making them ideal for large-scale hydrogen applications. This ensures the cooling circuit operates at peak efficiency throughout the service life of the fuel cell.

Catalyst Support

Designed to anchor catalyst materials or hold catalytic coatings, wire mesh ensures optimal reaction performance in hydrogen applications. Manufactured from robust alloys such as Inconel 600, Hastelloy C22, titanium, and nickel alloys, it resists corrosion and maintains stability under extreme conditions. Available in pleated, deep-drawn, and precision-cut formats, it adapts seamlessly to system requirements.

Behind every efficient hydrogen system is a filter designed to balance pressure drop and flow rate. Discover how this balance drives purity, saves energy, and extends service life.

Mesh size plays a crucial role in hydrogen filtration. Discover how precision-engineered wire mesh helps you strike the right balance between efficiency, flow, and long-term durability.

The performance of your wire mesh plays a critical role in hydrogen system efficiency. Learn how routine monitoring and timely replacements help maximize uptime and reliability.

Woven wire mesh is a highly versatile component in hydrogen production, playing an essential role in processes like PEM electrolysis, alkaline electrolysis, hydrogen fuel cells, and hydrogen storage systems. It serves as gas diffusion layers (GDLs) that ensure uniform gas distribution, membrane supports that prevent warping under high pressure, filtration media that capture foreign particles before they can damage sensitive components, and catalyst backings that stabilize active surfaces for maximum reactivity.

Because woven wire mesh is available in countless weave types, mesh counts, and metal alloys, it can be engineered to match precise performance requirements, whether you need to maximize throughput, enhance durability, or achieve ultra-fine particle retention. This adaptability makes it an ideal solution for optimizing efficiency, maintaining long-term reliability, and ensuring consistent performance in hydrogen systems.

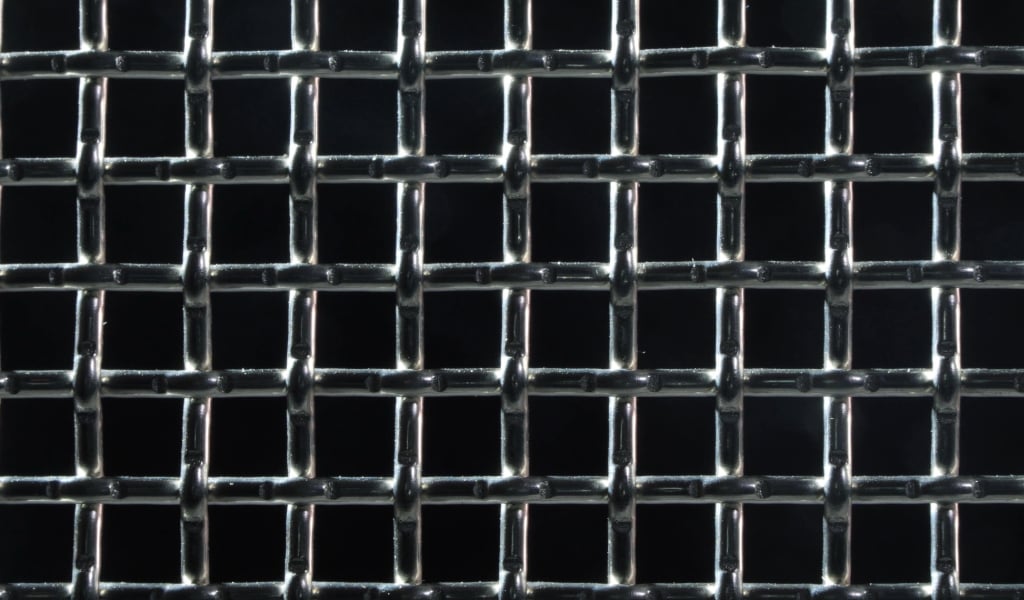

Unlike synthetic filter media, perforated plate, or sintered sheets, woven wire mesh offers precision, longevity, and design flexibility that directly translates into operational savings. Its uniform apertures guarantee predictable filtration performance, while its open structure maintains optimal flow rates with minimal pressure drop, critical for maximizing hydrogen output.

Manufactured from stainless steel alloys such as 316L or 904L, woven mesh is inherently corrosion-resistant, able to withstand harsh electrolytic environments, high operating pressures, and extreme temperatures without degradation. This means fewer maintenance interventions, longer service intervals, and reduced downtime, giving you both immediate and long-term ROI. Additionally, because woven mesh is easy to clean and reusable, it offers sustainable value compared to disposable alternatives.

Absolutely. Woven wire mesh is integral to both PEM and alkaline electrolysis systems, helping achieve higher hydrogen production rates while lowering energy consumption. In gas diffusion layers, mesh ensures even gas flow across the membrane surface, eliminating dead zones and hotspots that could cause uneven wear or reduced efficiency.

As a membrane support layer, it maintains flatness and structural stability under high differential pressures, minimizing the risk of mechanical failure. The result is improved current density distribution, optimized reaction kinetics, and reduced ohmic losses, all of which contribute to higher overall system efficiency. When correctly specified, woven mesh can extend component lifespan while delivering a measurable boost in hydrogen output.

Purity is one of the most critical metrics in hydrogen production, especially when the hydrogen will be used in fuel cells or high-spec industrial applications. Contaminants, even at trace levels, can poison catalysts, cause membrane degradation, clog downstream piping, and lead to costly operational interruptions.

Woven wire mesh provides an efficient pre-filtration or final filtration stage, trapping particulates before they enter sensitive system components. With precision-controlled aperture sizes, mesh can be tailored to stop particles at micron-level dimensions without significantly affecting flow rate. This ensures compliance with stringent gas purity standards, protects expensive equipment from damage, and preserves the efficiency and lifespan of the entire hydrogen production chain.

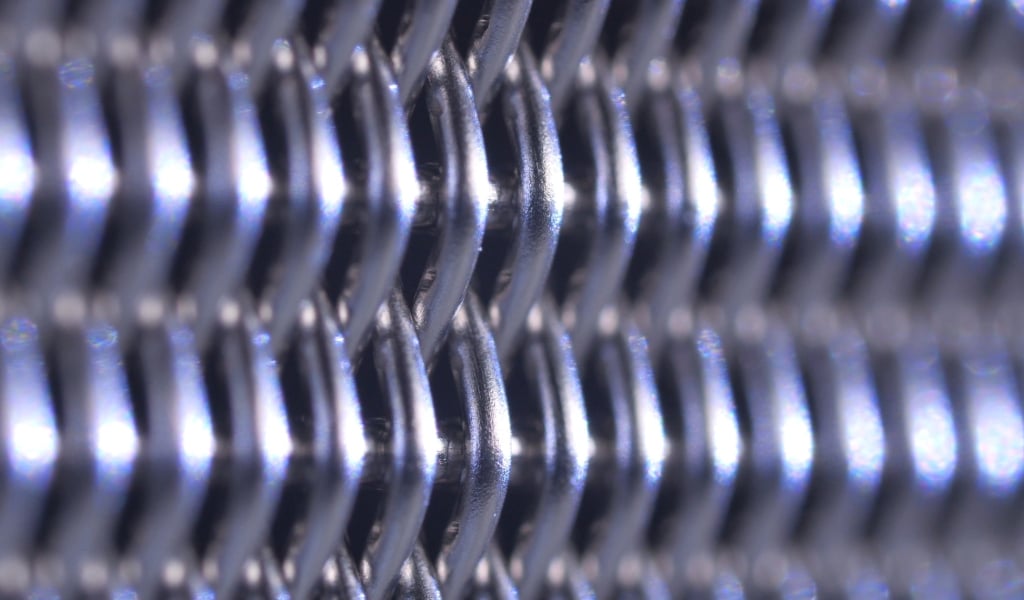

The right mesh specification depends on the process type, operating environment, and performance priorities of your hydrogen system. For example, fine mesh counts with smaller wire diameters may be ideal for high-purity filtration, while heavier wire diameters and coarser mesh counts offer greater structural support in membrane applications.

Material choice is equally important; 316L stainless steel is often preferred for its corrosion resistance and mechanical strength, while exotic alloys like Hastelloy or Inconel may be selected for extreme chemical or thermal environments. Weave type (plain, twill, or Dutch weave) can also be customized to balance flow characteristics with particle retention. Our engineering team collaborates with customers to match mesh design to precise application needs, ensuring optimal flow performance, durability, and cost-efficiency.