Precise Filtration Starts with the Right Mesh

Mesh specifications define filtration success. The right design ensures accurate particle capture, handles heavy loading, and supports easy cleaning, keeping your system efficient and reliable.

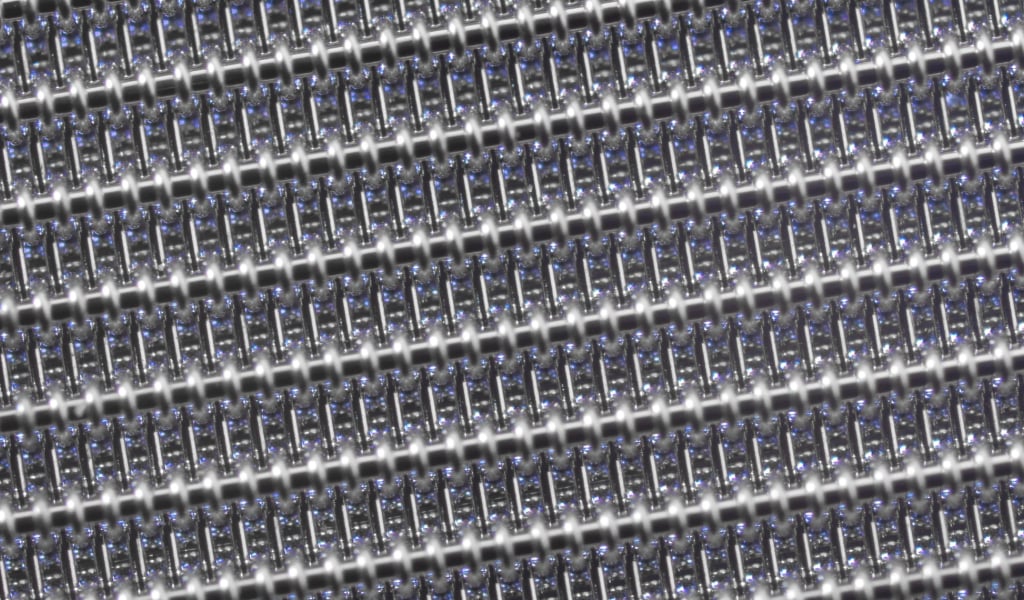

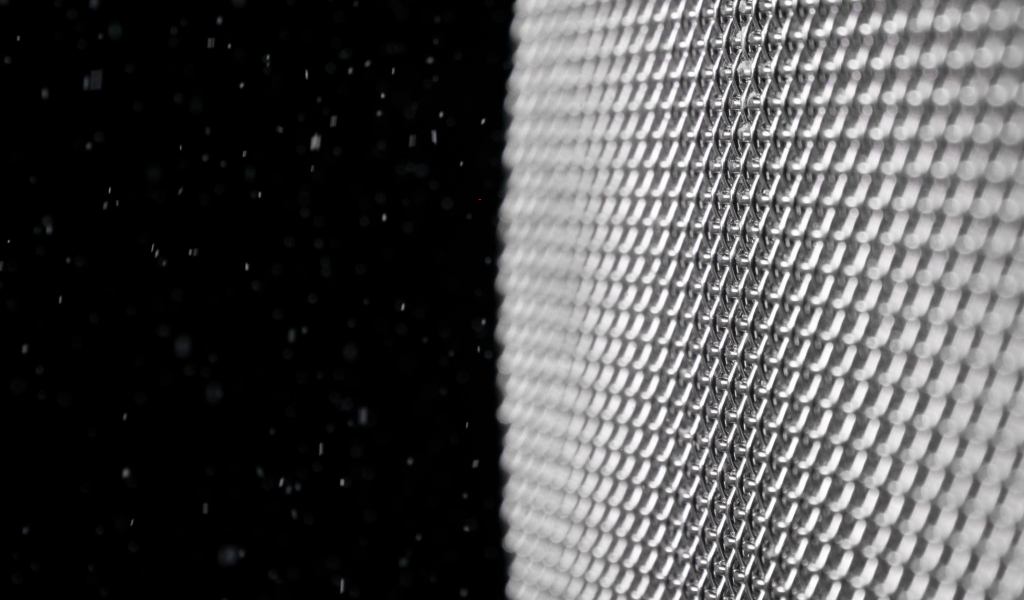

When efficiency and durability matter, woven wire mesh delivers unmatched performance in hot gas filtration systems. Engineered for rigid stability under pressure variations, this material ensures consistent filtration even in fluctuating environments.

Its high-temperature resistance makes it ideal for applications where heat can compromise other filter media, while superior corrosion resistance protects against aggressive gases and harsh chemical exposure. Designed to endure countless maintenance cycles without losing integrity, woven wire mesh offers a long service life and reduced downtime, making it the most cost-effective and reliable choice for industrial filtration.

Whether you’re optimizing performance or minimizing operational risks, woven wire mesh stands as the proven solution for cleaner, safer hot gas filtration.

Extreme heat can push filtration systems to their limits, impacting mesh integrity, efficiency, and safety. Learn practical strategies for selecting materials, designing for thermal stress, and maintaining performance when temperatures soar. These insights help you prevent costly failures and keep your process running at peak reliability.

Hot gas filtration isn’t just about the mesh pattern, it’s about survival in extreme conditions. High temperatures and corrosive gases can weaken or destroy the wrong material, leading to failures, contamination, and costly downtime.

Choosing the right alloy ensures:

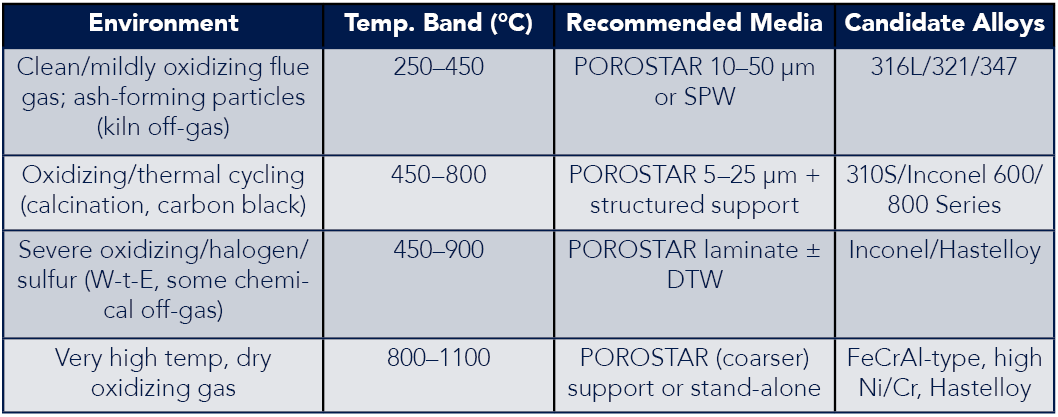

Your operating environment drives material choice. This table helps you match mesh specifications and alloys to your conditions, so your filtration system performs flawlessly.

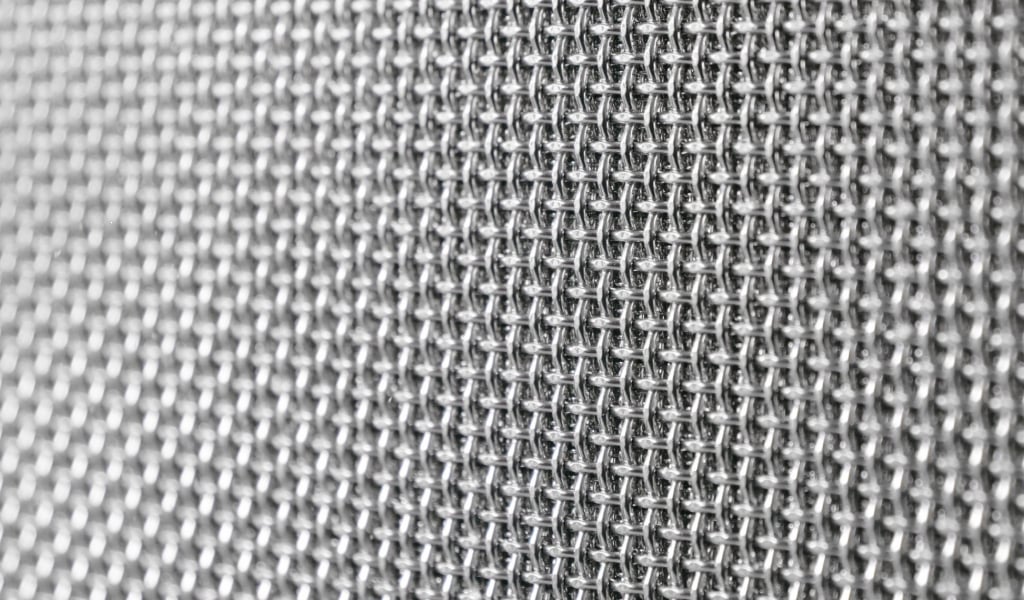

Hot gas filtration isn’t one-size-fits-all. Your target cut-point, particle loading, and cleanability requirements determine how the mesh behaves in real-world conditions. The wrong specification can lead to clogging, poor separation, and excessive downtime.

Choosing the right mesh design ensures:

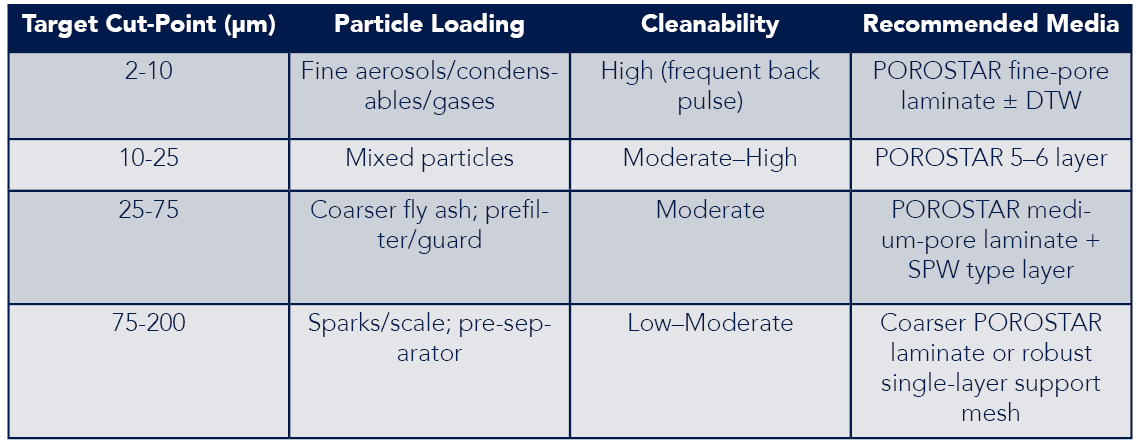

This table helps you align mesh specifications with your process goals—so your system runs cleaner, longer, and more reliably.

Mesh specifications define filtration success. The right design ensures accurate particle capture, handles heavy loading, and supports easy cleaning, keeping your system efficient and reliable.

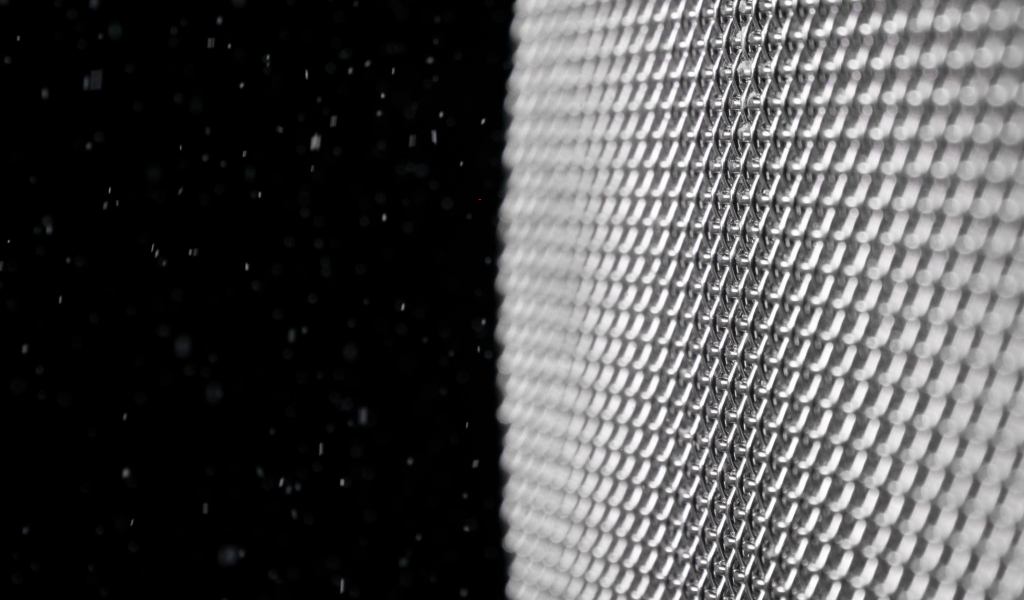

Hot gas filtration systems rarely fail overnight, but may degrade gradually. Early signs like reduced flow, rising pressure drop, or uneven cleaning cycles signal that your mesh may be losing efficiency. Catching these issues early prevents contamination, protects equipment, and avoids costly downtime.

When hot gas filtration underperforms, the impact goes far beyond clogged mesh. Energy waste, increased maintenance, and unplanned downtime quietly erode profitability. Understanding these unseen costs is key to protecting your process and your bottom line.

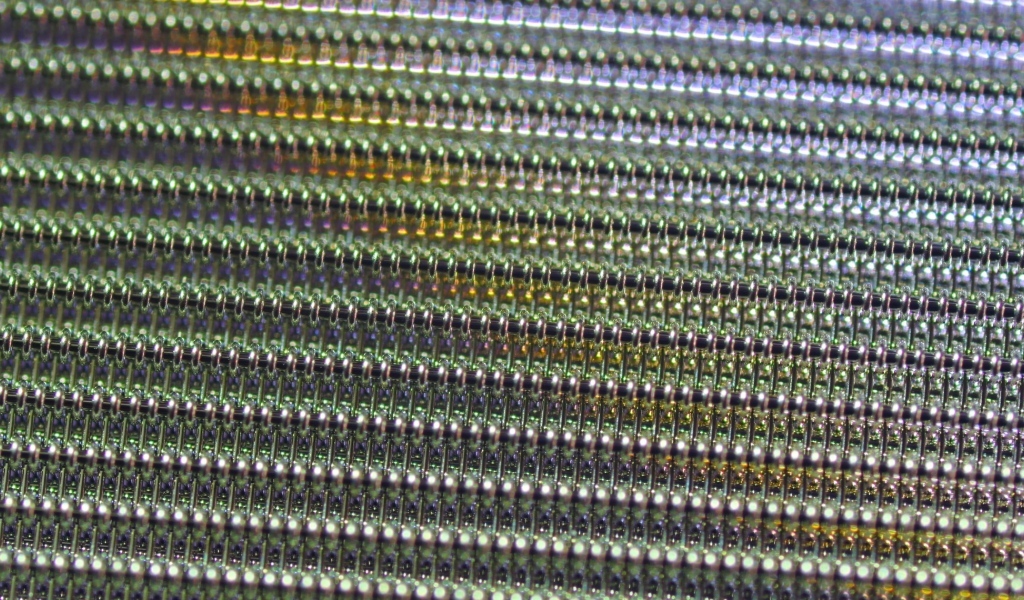

Woven wire mesh is the preferred solution for hot gas filtration because it combines precision, durability, and adaptability in environments where other filter media fail. Unlike non-metallic filters, wire mesh maintains structural integrity at temperatures exceeding 1000°F (538°C) and resists thermal fatigue, oxidation, and chemical attack. Its uniform openings deliver consistent particle capture, which is critical for processes requiring tight cut-points and product purity. Additionally, woven wire mesh offers superior cleanability and reusability, reducing downtime and operating costs compared to disposable filters. Industries such as chemical processing, power generation, and metallurgy rely on woven wire mesh because it ensures reliable performance under harsh conditions, supports sustainability, and minimizes total cost of ownership.

Alloy selection is one of the most important decisions for hot gas filtration because temperature and gas chemistry directly impact material performance. For moderate temperatures and mild corrosion, stainless steel grades like 304 or 316 are common due to their balance of strength and corrosion resistance. For extreme heat or aggressive chemical environments, nickel-based alloys such as Inconel or Hastelloy are preferred because they resist oxidation and maintain mechanical strength under thermal stress. Key factors to consider include:

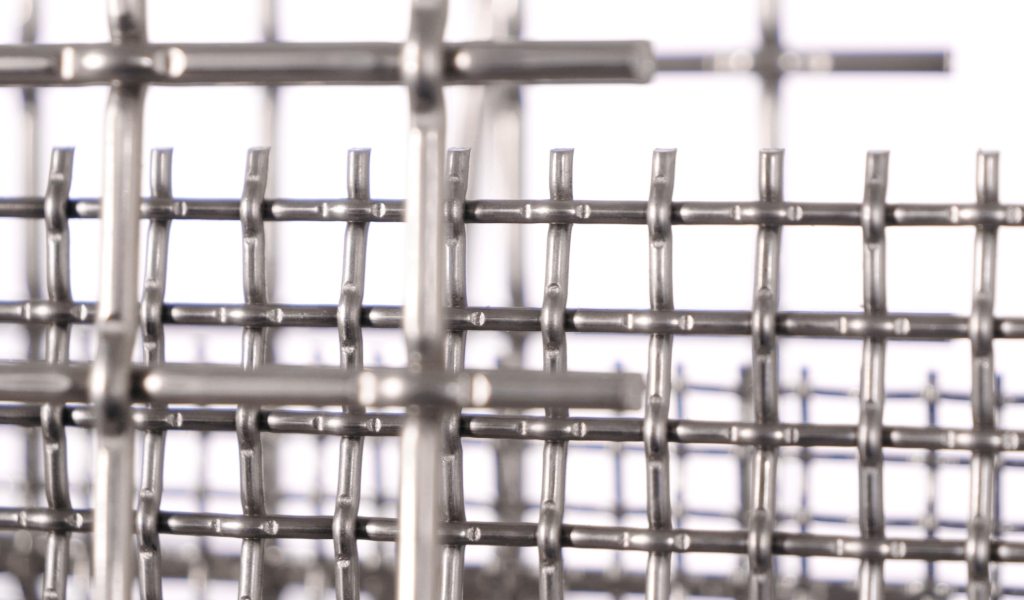

Mesh specifications—mesh count, wire diameter, and weave type—directly determine filtration performance. A finer mesh provides a tighter cut-point for capturing smaller particles but increases pressure drop, which can affect flow rates and energy consumption. Coarser meshes improve flow but sacrifice precision. Weave patterns such as plain weave (simple and stable) or twill weave (added strength and flexibility) influence cleanability and mechanical stability. Balancing these specifications ensures:

Yes! In fact, this is one of the biggest advantages of woven wire mesh. Unlike disposable filters, wire mesh can be cleaned through backflushing, thermal regeneration, or chemical cleaning, depending on the contaminants and operating conditions. Proper cleaning restores filtration performance and significantly reduces replacement costs. Implementing a regular cleaning schedule not only extends filter life but also ensures consistent process efficiency. This makes woven wire mesh a sustainable solution for industries where downtime and consumable costs are major concerns. For best results, cleaning methods should be matched to the type of fouling and alloy used.

Detecting degradation early prevents costly failures and contamination. Common indicators include: