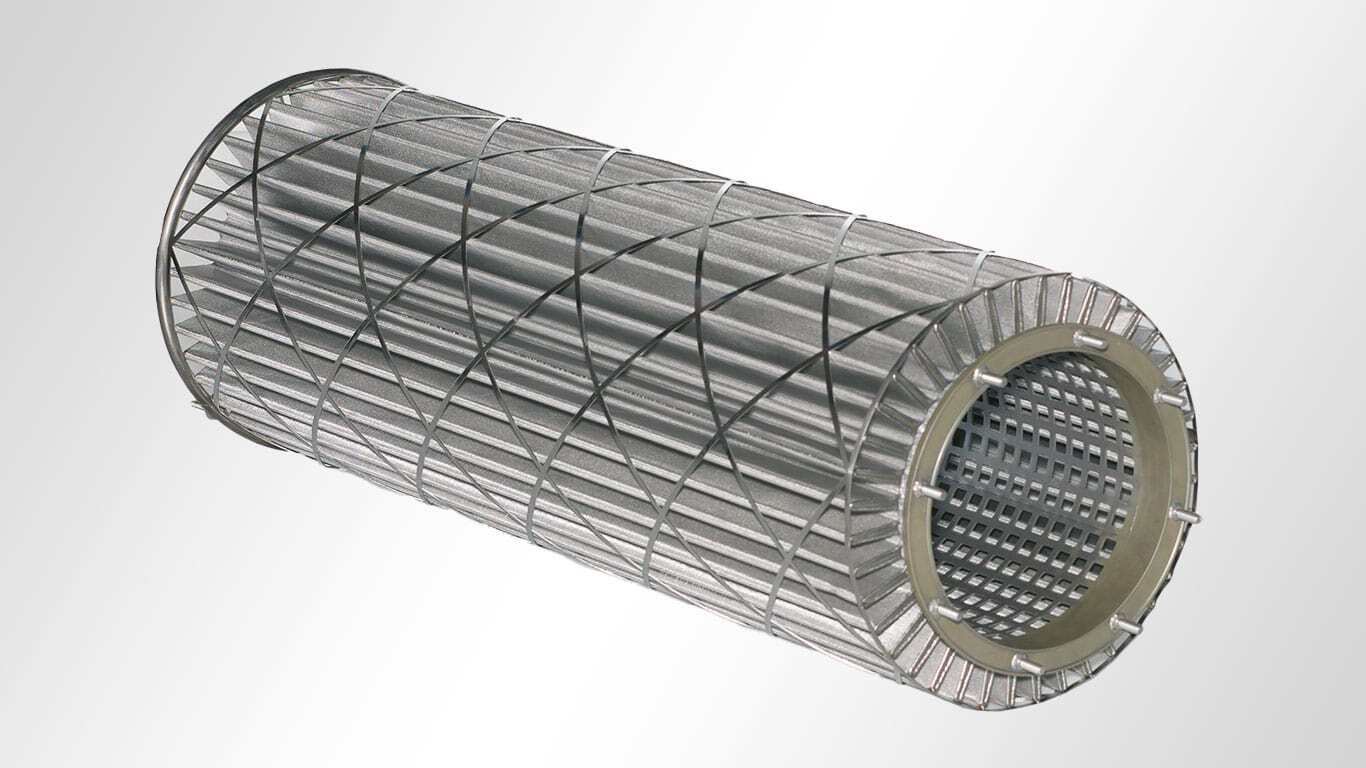

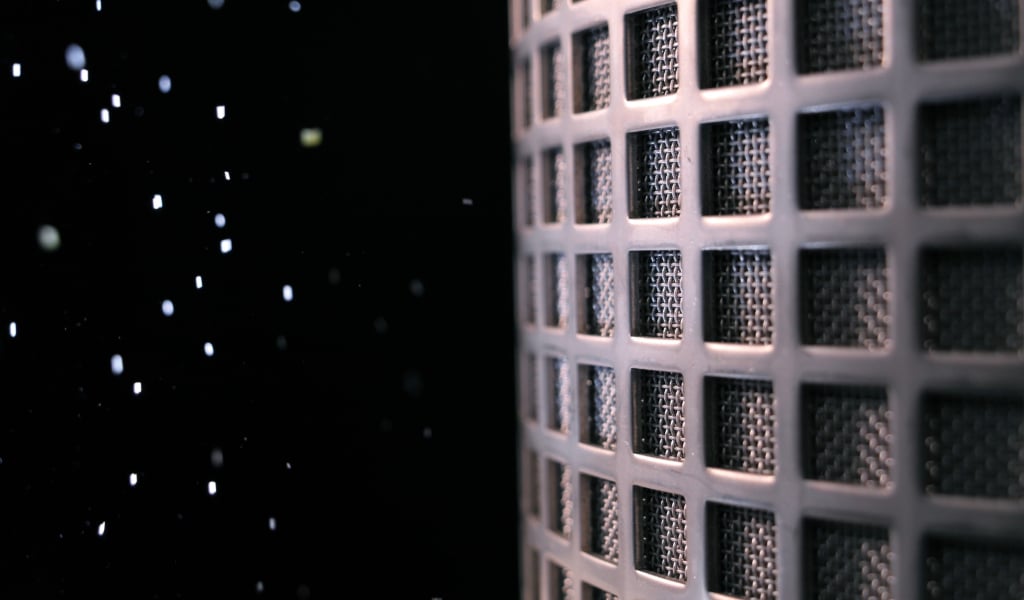

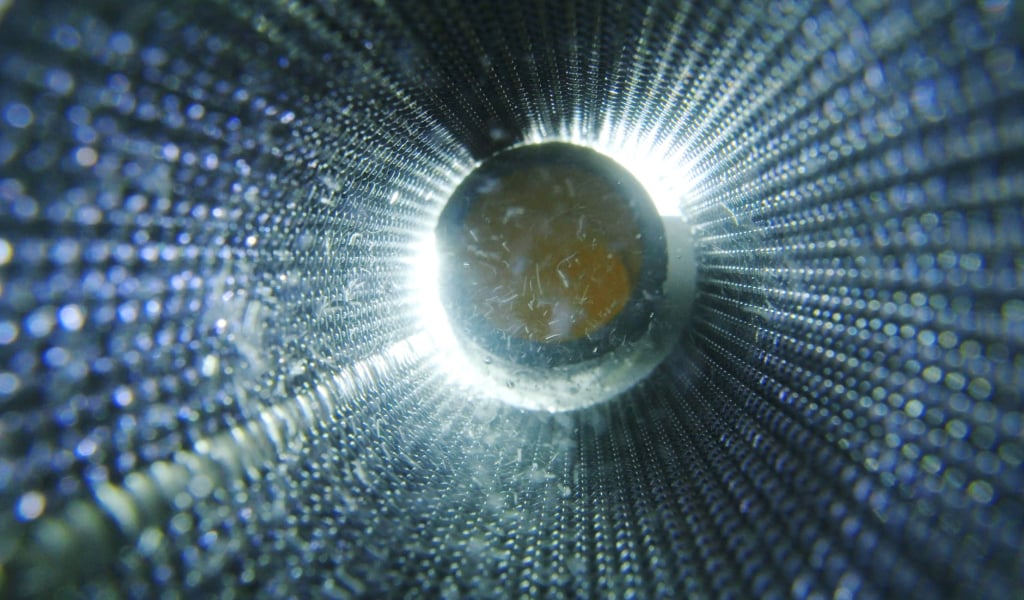

Woven wire mesh significantly improves water filtration performance by offering precise and repeatable pore sizes, which enable consistent particle capture and reduce the risk of bypass. Unlike granular media or non-woven fabrics, wire mesh provides a rigid, uniform structure that maintains its integrity under high pressure and flow conditions.

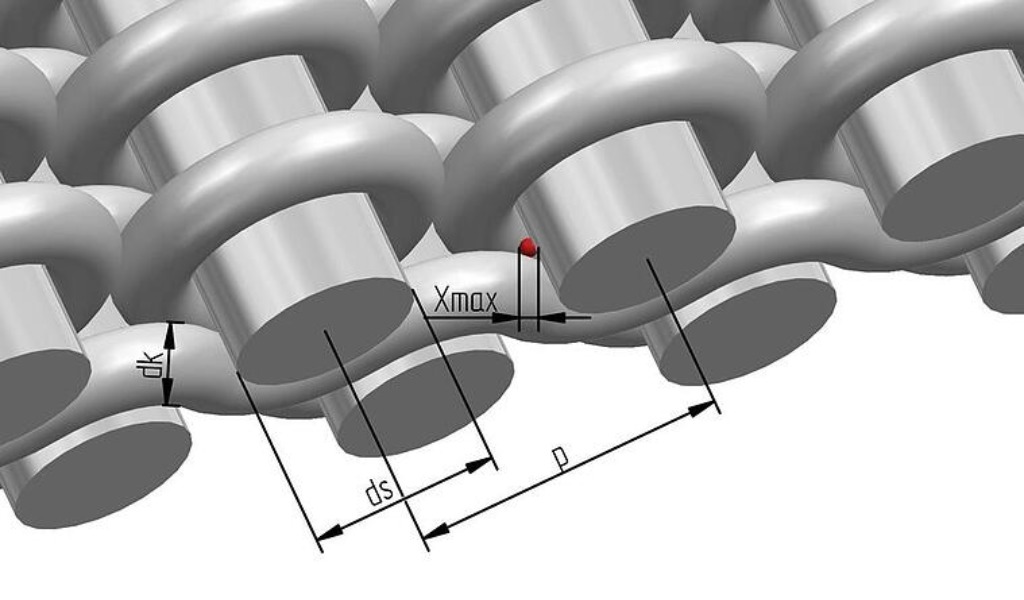

This results in higher filtration accuracy, lower maintenance, and longer service life. Additionally, woven mesh allows for custom weave patterns, such as plain, twill, or Dutch weaves, that can be tailored to specific filtration goals, including sediment removal, microbial reduction, or chemical separation. These features make it ideal for industrial water treatment, municipal systems, and high-purity applications.

Not to mention, woven wire mesh can be pleated to significantly increase surface area, boosting filtration capacity without compromising flow. Its high precision and consistent structure ensure reliable performance, making it a valuable enhancement in advanced water treatment systems.