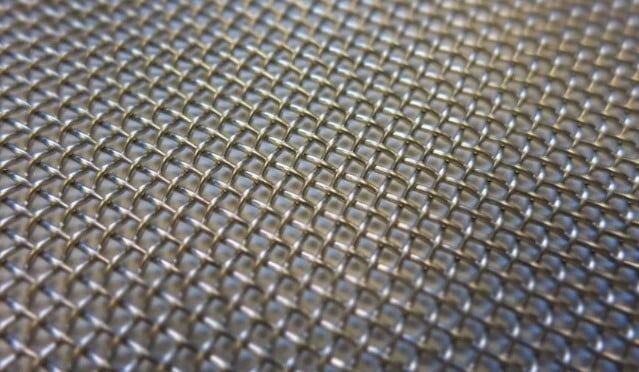

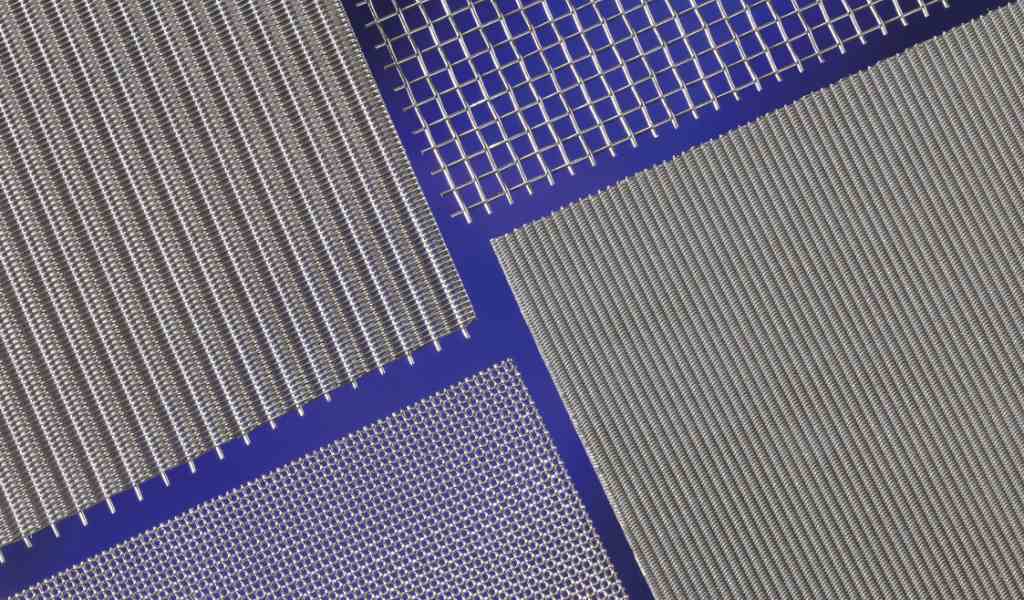

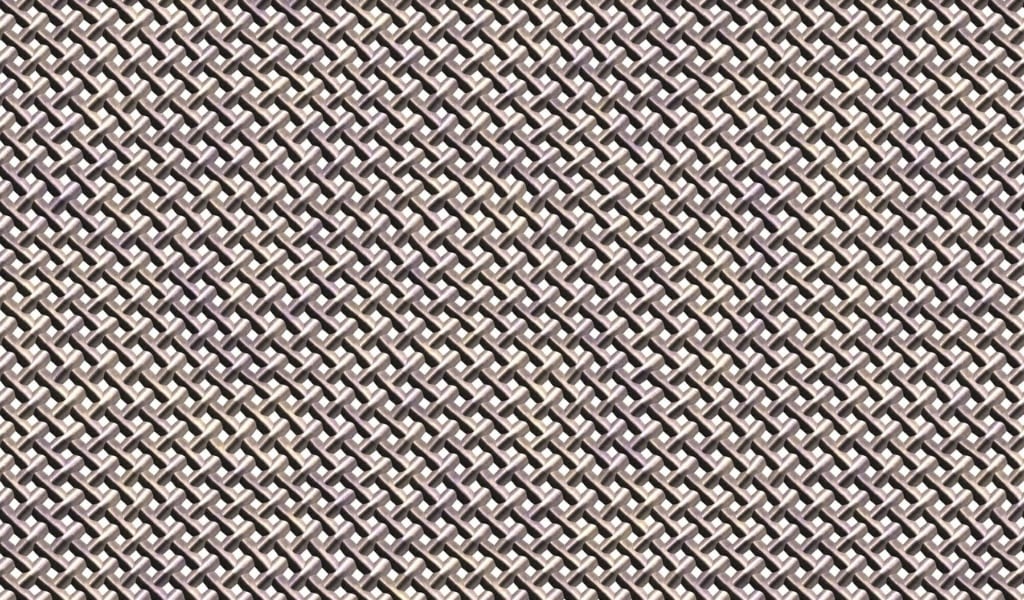

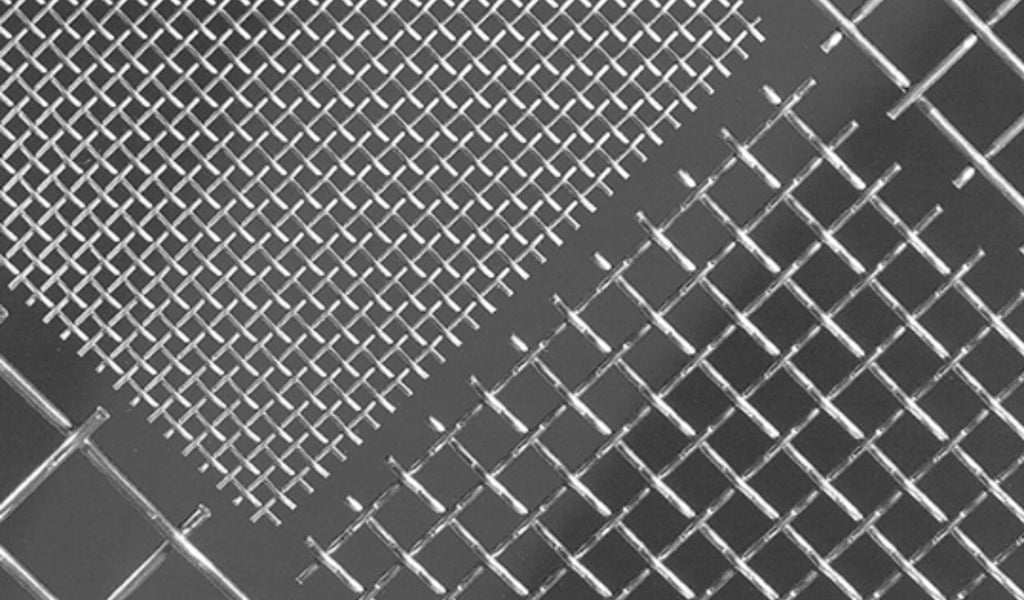

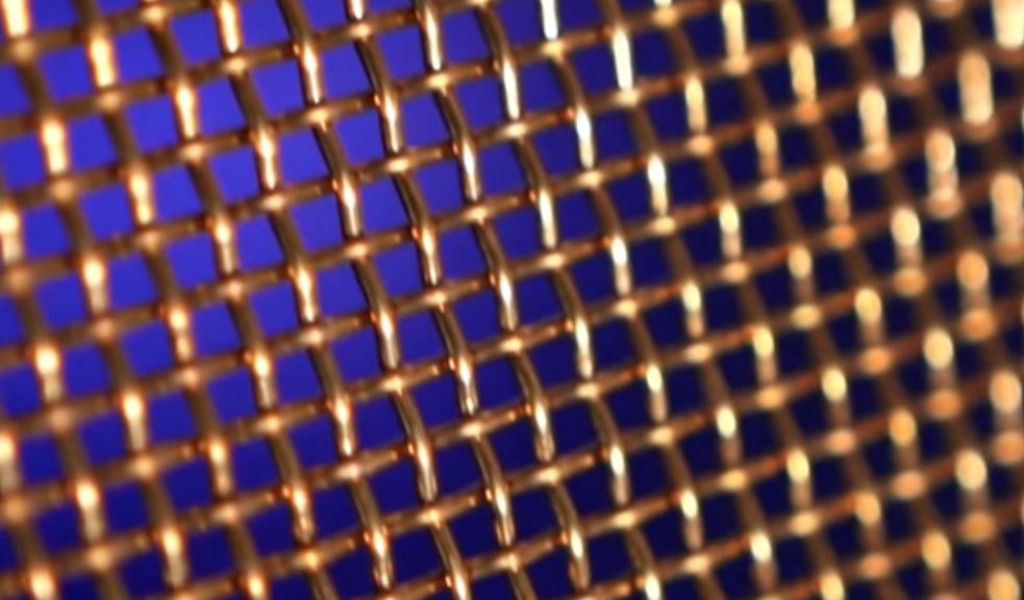

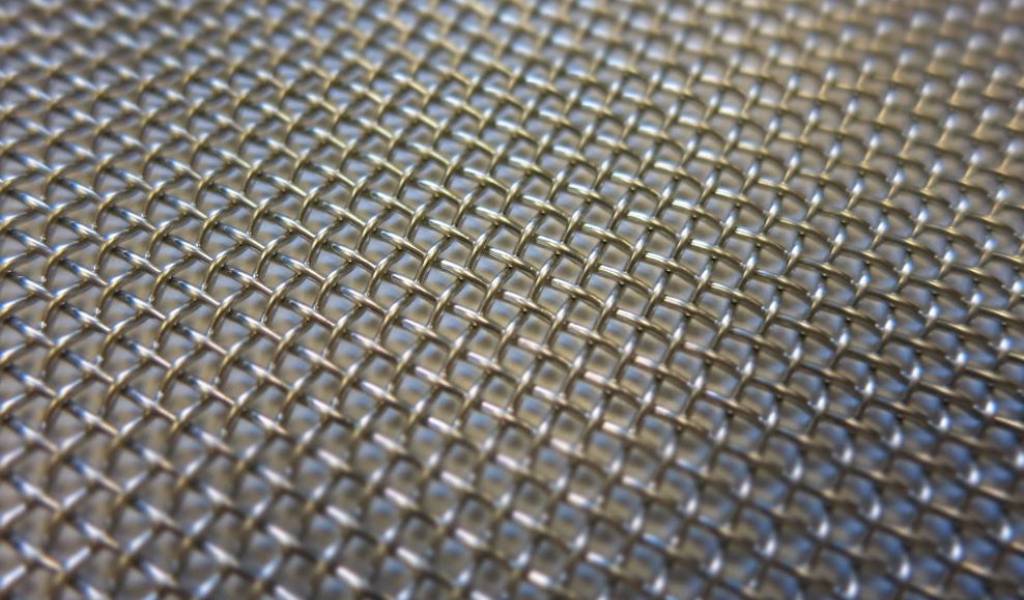

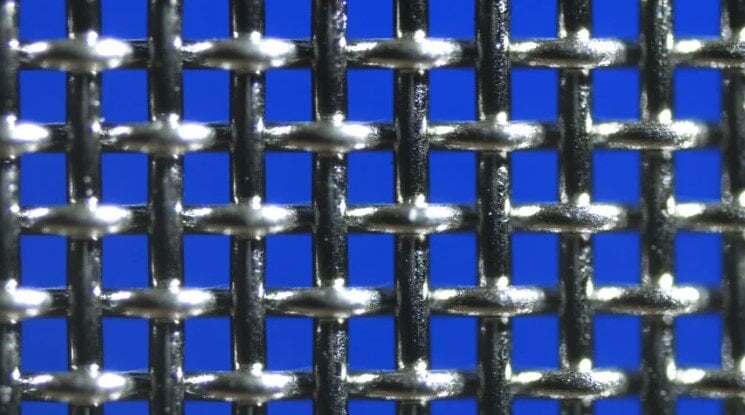

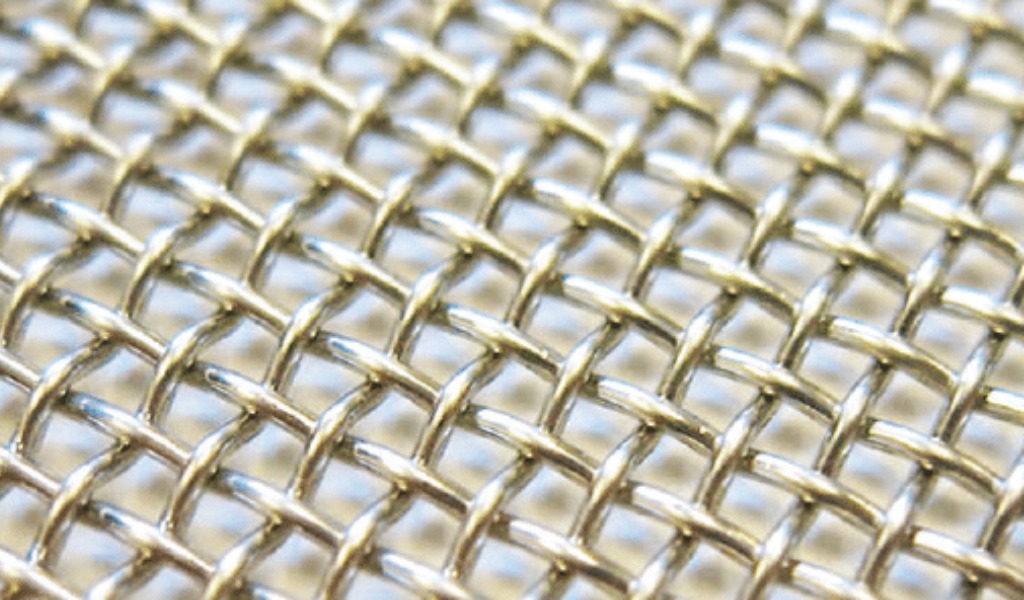

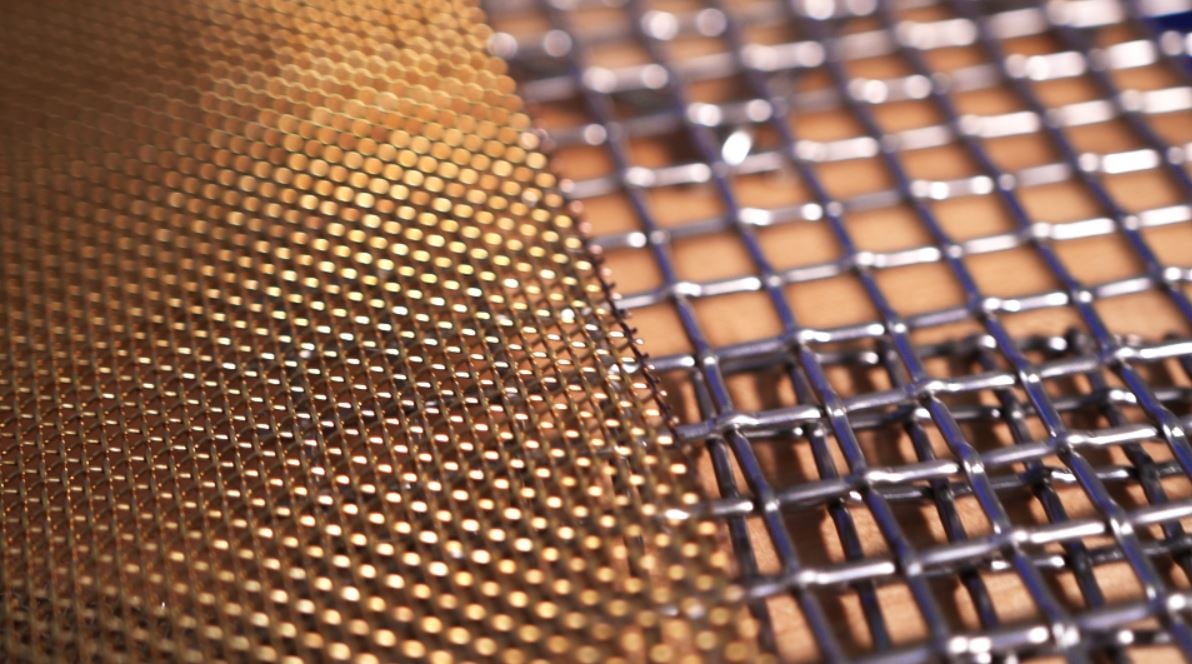

Yes. In fact, customization is where woven wire mesh truly excels. W.S. Tyler produces mesh with engineered control over wire diameter, mesh count, and open area, allowing you to fine-tune the mesh for the exact shielding effectiveness needed across your frequency range. Mesh can also be formed into custom gaskets, cylindrical filters, or multi-layered composite panels, depending on the application's shape, airflow needs, and EMI threat level.

Need to meet military, aerospace, or medical EMC standards? We work with engineers to ensure mesh solutions are certified, scalable, and integration-ready, whether you’re designing for a prototype or mass production. The ability to fabricate shielding mesh with tight tolerances and material consistency makes it ideal for critical environments where failure is not an option.