Efficiency Begins with Layer Setup

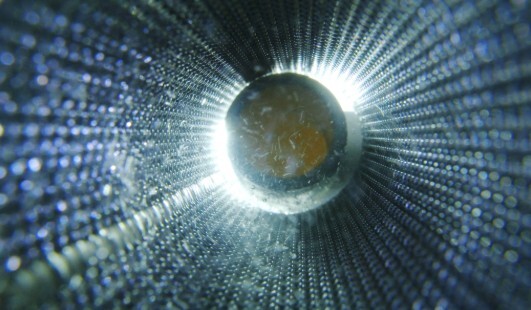

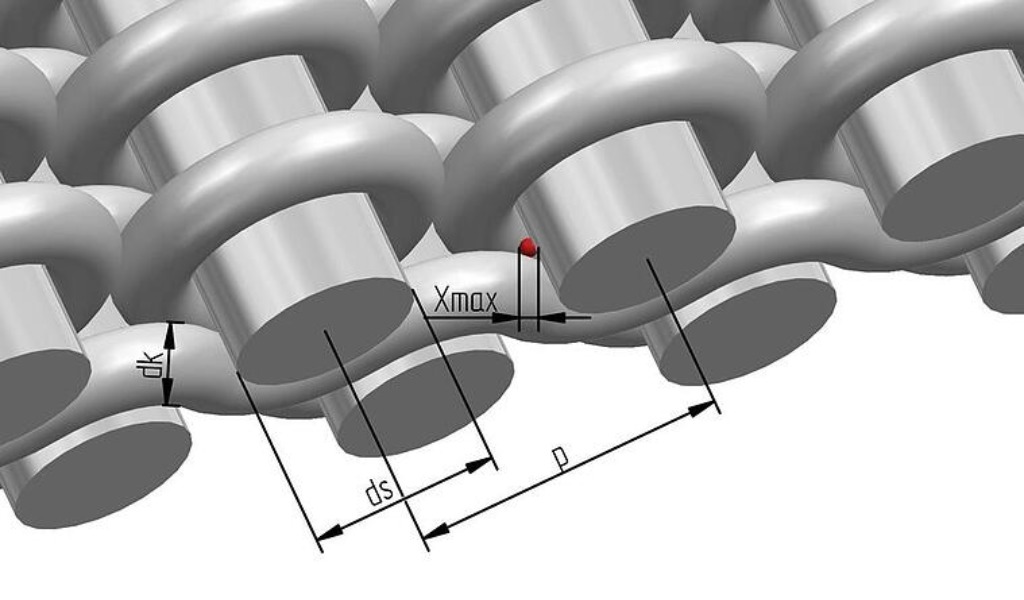

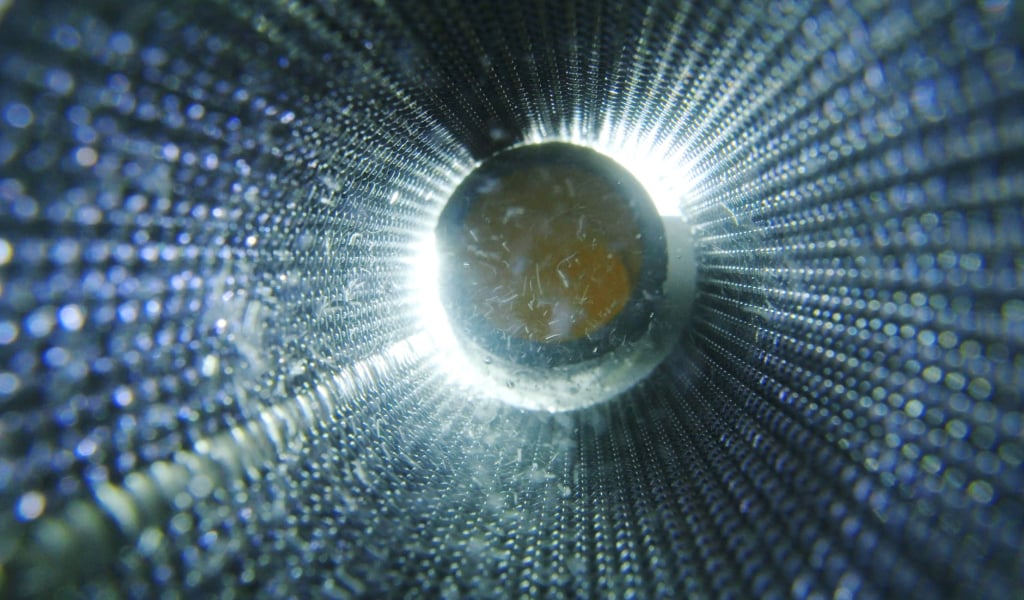

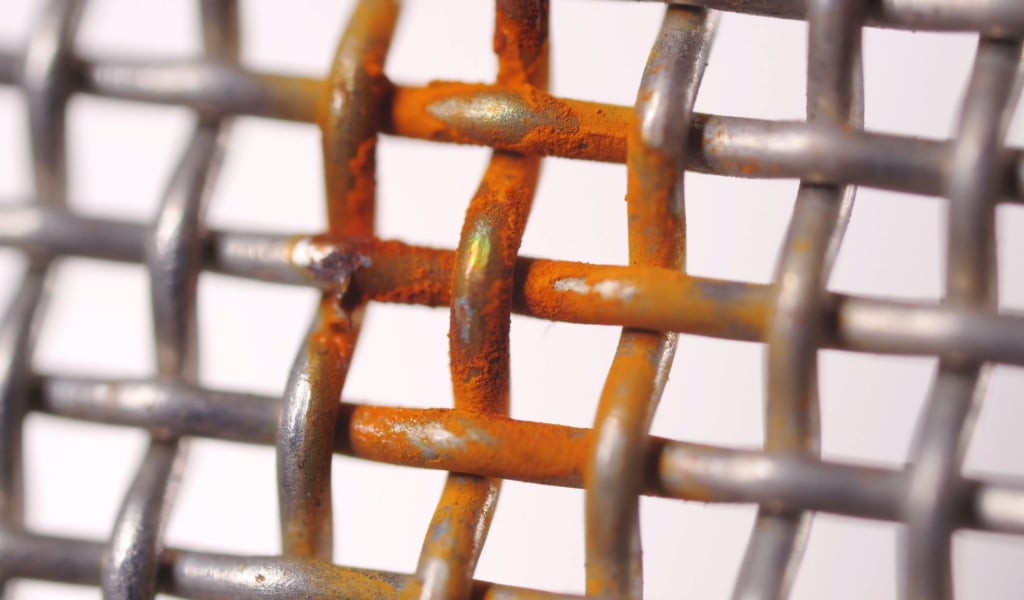

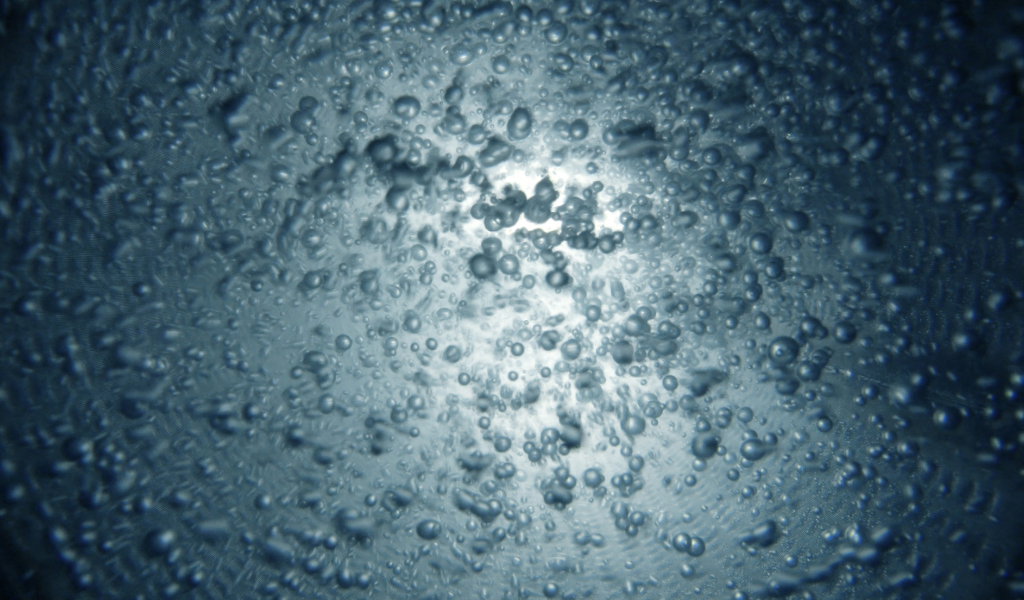

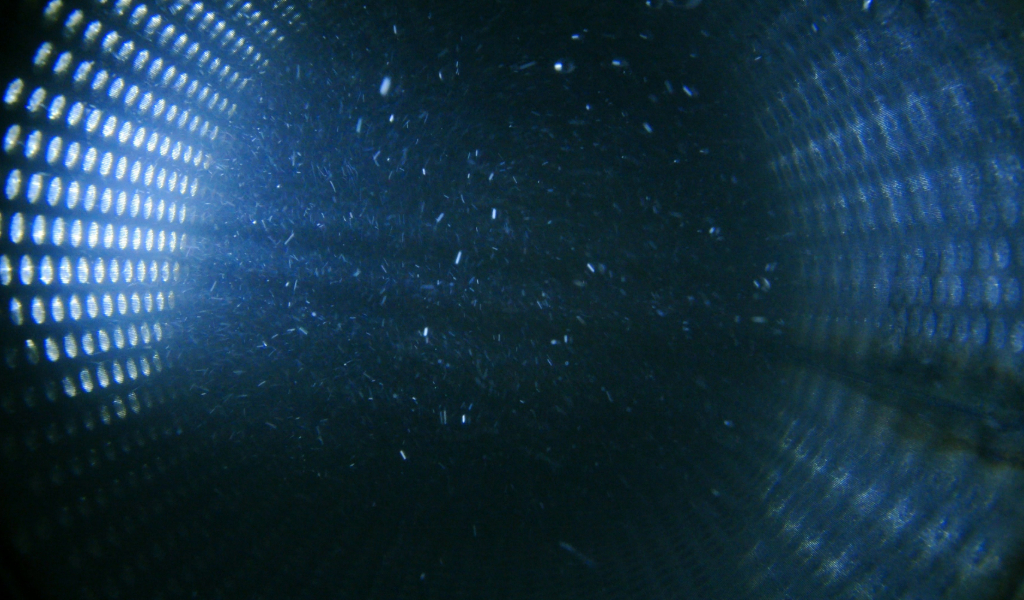

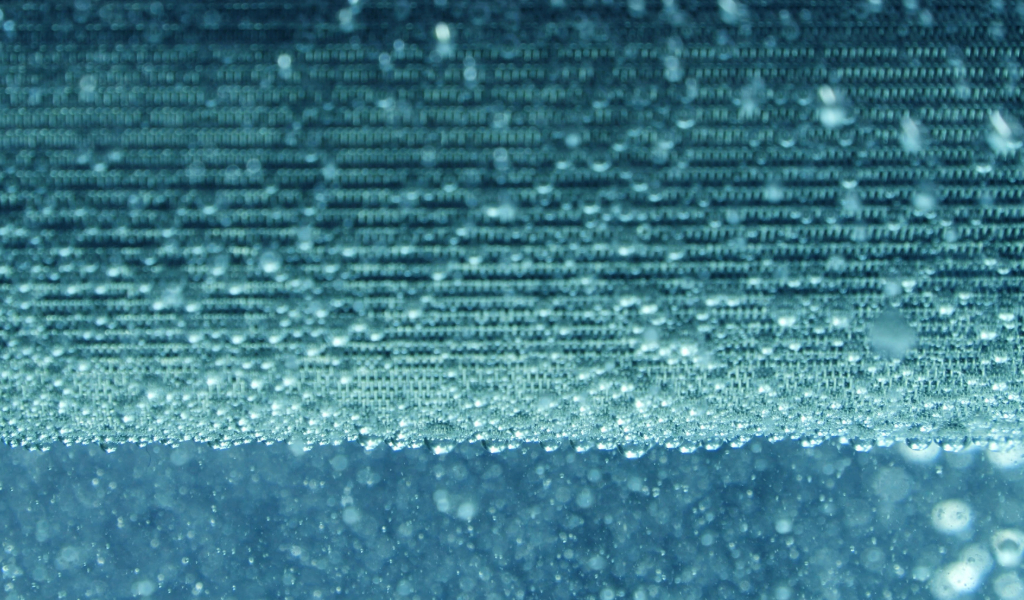

The structural differences between sintered and multilayer mesh screens directly impact filtration precision, durability, and resistance to fouling. Choosing the right mesh type is essential for maintaining consistent flow, minimizing maintenance, and optimizing long-term system efficiency in desalination environments.