Long-lasting Performance

Made Easy

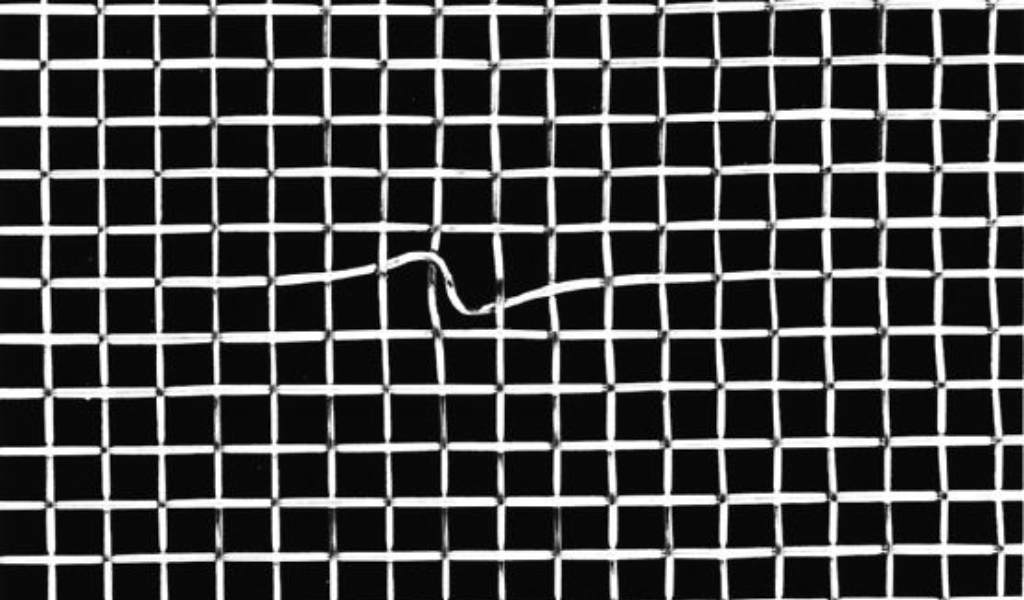

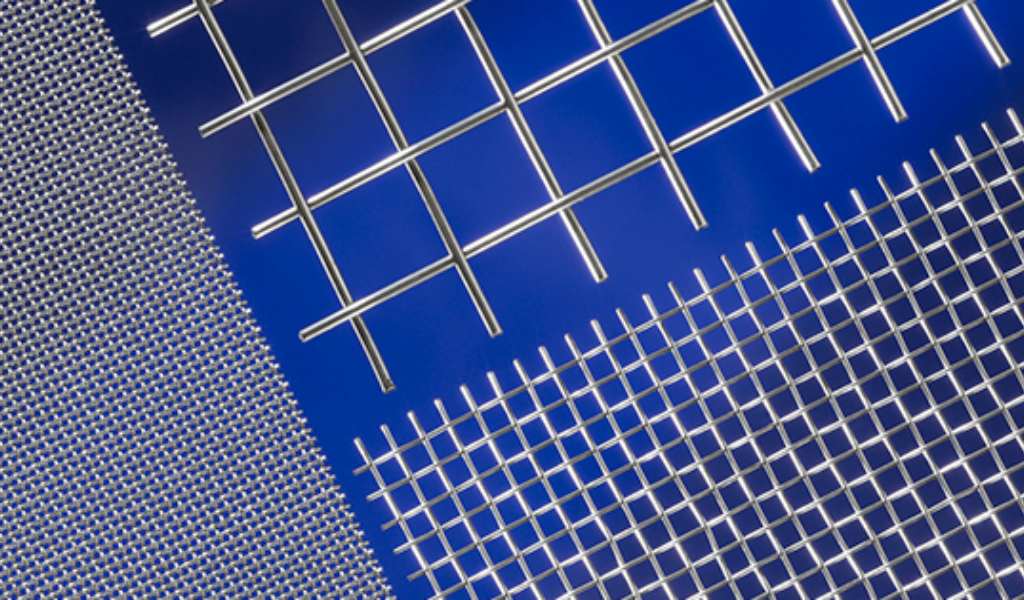

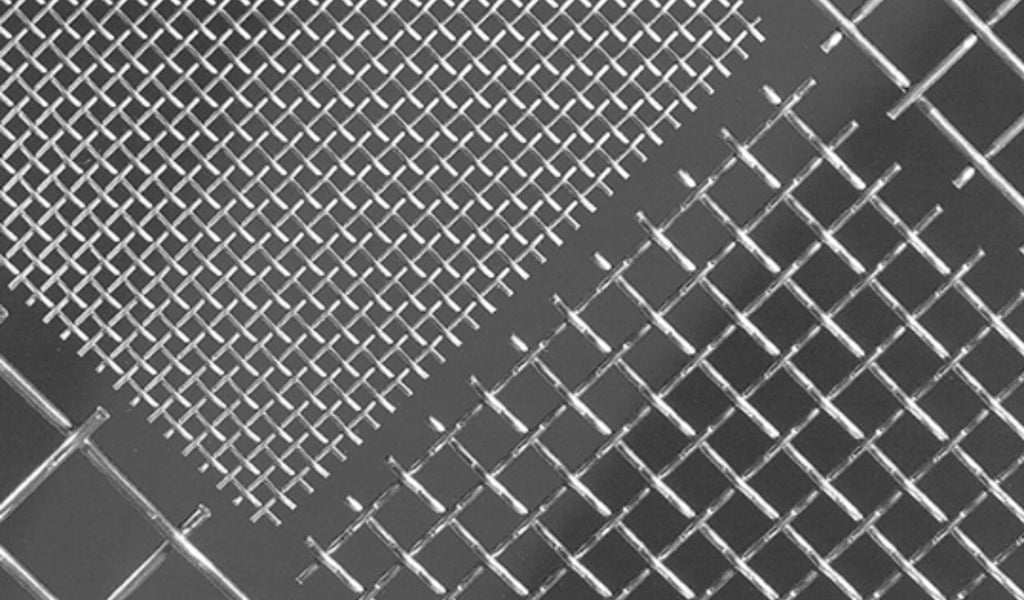

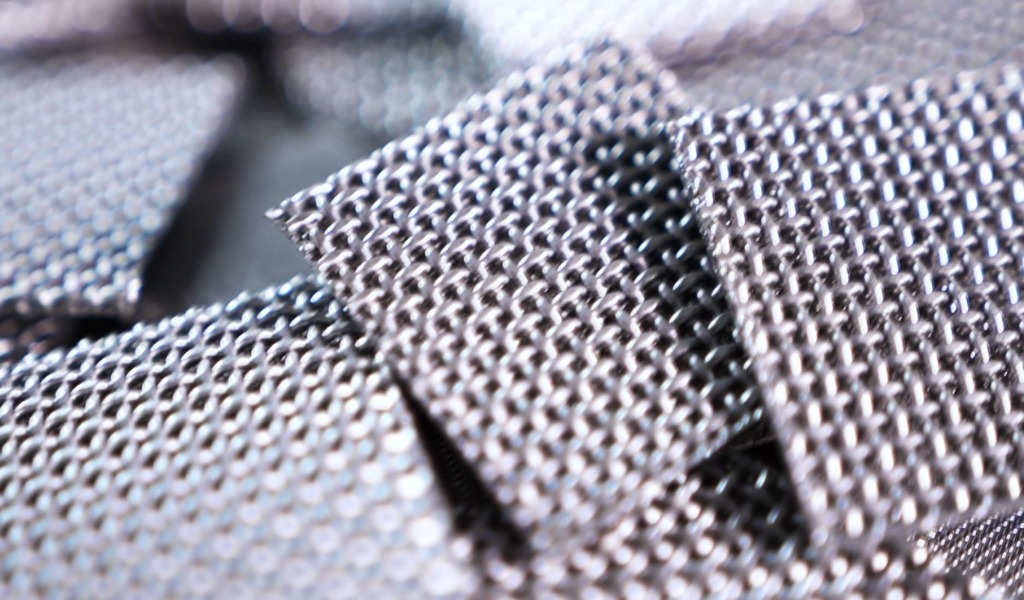

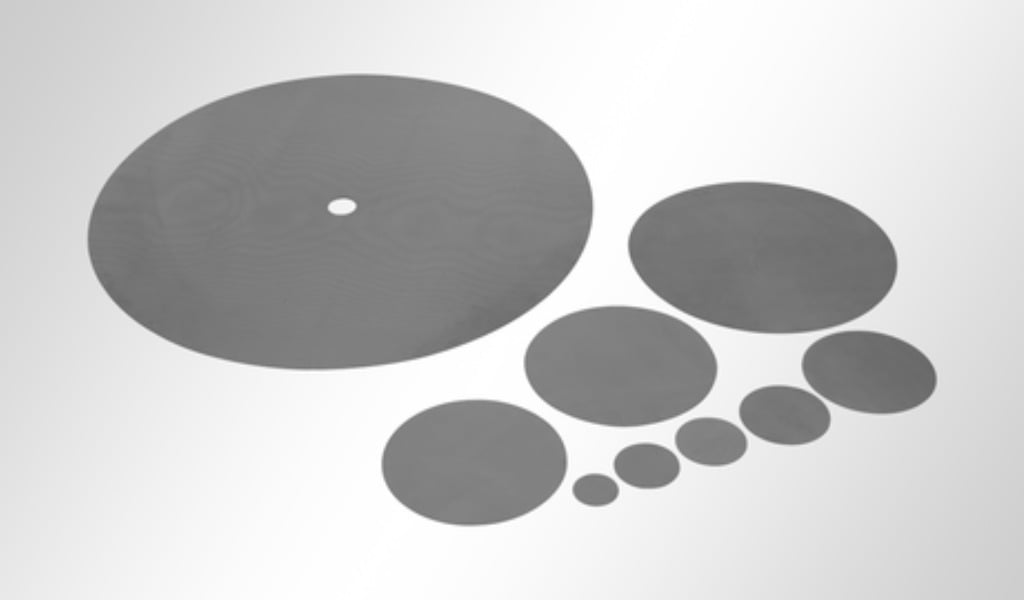

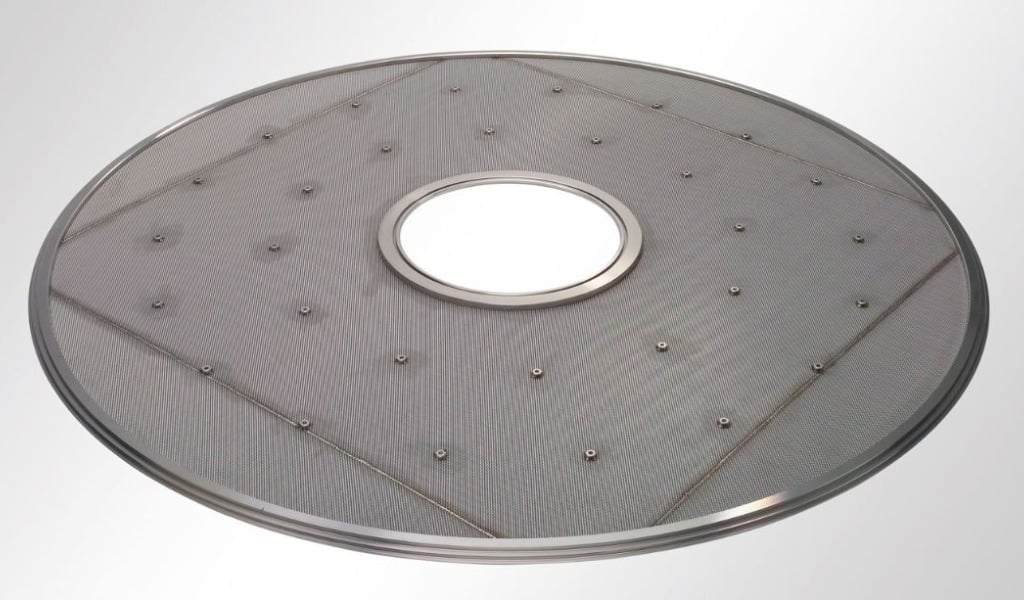

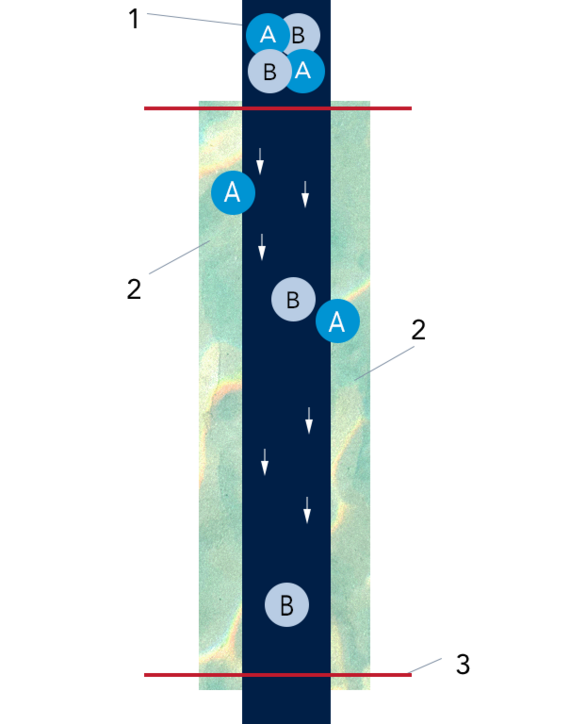

The best way to prolong the lifespan and performance of your woven wire chromatography filter plates is regular maintenance. As they are constructed from stainless steel, they can be wiped clean, backflushed, and freed of all debris with relative ease.

.jpg)