As one of the most unique materials in the world of architectural design, architectural wire meshoffers the qualities needed to transform any vision into reality. To help you determine if it can enhance the aesthetic of your next project, we created this guide to provide insight into everything you need to know about architectural wire mesh.

Fill out the form for a downloadable PDF version of the guide you can reference later. (Don't forget, you can keep scrolling to read without giving us your email!)

Looking for something specific? Use the buttons below to be directed to a particular subject.

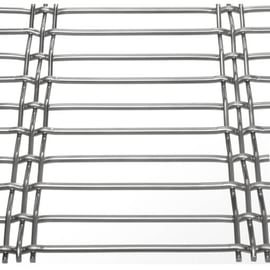

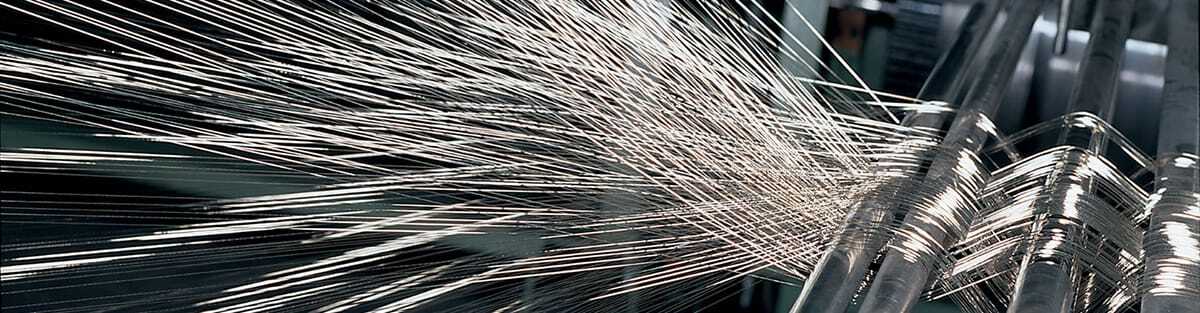

Stainless Steel Architectural wire mesh is a series of high-tensile, grade 316 stainless-steel wires interlocked together and is commonly produced from 70% recycled material. The individual wires are woven on large weaving looms at Haver & Boecker, our German-based parent company, using a similar technique used to make clothes.

While it appears rigid and unyielding, stainless steel architectural mesh proves to be fairly flexible when a certain length is reached. Because of this characteristic, architectural mesh panels can be applied to countless applications.

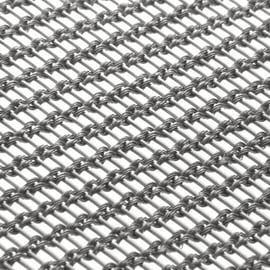

The term weave type refers to the way in which the warp and weft wires cross each other. It encompasses four different mesh categories: Woven wire, Cable, Fine, and Specialty.

Wire mesh is best defined as an assortment of rigid wires that have been woven together to form a sheet of mesh that is interlaced.

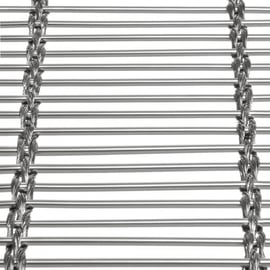

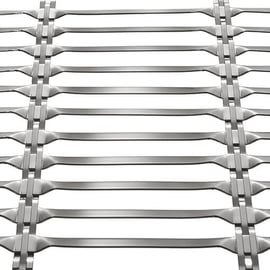

Cable mesh is a mesh type that is woven on a specialized weaving loom, much like woven wire. The key difference between the two is that cable mesh uses cables rather than stainless steel wires in the warp (vertical) direction.

Mesh profiles that are constructed out of wires that have a very small wire diameter. Fine mesh is particularly sensitive when introduced to mechanical stresses. That said, the application of the mesh is a key factor when classifying fine mesh.

Specialty mesh is a mesh that features a unique pattern and carries the characteristic of employing several different wire types.

A weaving loom that is specifically designed to properly weave stainless steel wires is employed to weave architectural mesh. These looms consist of a warp beam, heddle frames (predetermined amount), a reed, a rapier band, and a front take-up mechanism.

The warp wires are the wires that run lengthwise and are fed directly from the warp beam.

The weft (or shute) wires are the wires that run across the width of the cloth during the weaving process.

The warp beam is a cylindrical drum that is wound with a specific number and length of warp wires depending on the mesh profile and size of the mesh panel. These specifications are calculated prior to winding the wires.

Heddle frames are holders used to separate the warp wires. Each loom contains at least two heddle frames. In a loom that uses two heddle frames, heddle frame 1 initially lifts half of the warp wires while heddle frame 2 pulls the other half down. The heddle frames switch positions after the weft wire is driven between the two sets of warp wires.

A rapier band is the mechanism that drives the weft wire between the two sets of warp wires after each heddle frame cycle.

A reed is the instrument that holds the warp wires in the desired spacing while also driving the weft wire into position.

Lastly, the finished roll of woven wire cloth is wound onto a front take-up mechanism and is removed in increments needed by the framing system of the project.

Once the beam is wound, and the heddle frames and reed are threaded, the whole assembly is transported to a weaving loom. The setup of the loom is then completed by a dedicated technician.

Once assembled, the weaving process is virtually automatic and seamless.

As the loom starts up, the warp beam begins to unwind in very small increments. The front take-up mechanism simultaneously winds the woven cloth at the same small increment in the same direction.

This movement allows the loom to maintain specific tensioning, which is critical when producing high-quality mesh panels.

As the two beams rotate, heddle frame 1 pulls half of the warp wires up while heddle frame 2 drives the other half down. It's at this point that the rapier, whether a two-part or one-part rapier, drives a weft wire between the two sets of warp wires.

Each weft wire is delivered from a separate spool of wire located at the side of the loom. As the rapier returns to its resting position to gather another weft wire, the reed pushes the latest weft wire into its final position.

This process is what creates the precise cross-sections needed to create the perfect aesthetic.

Once the weft wire is in place, the reed returns to its original position. The warp beam and front take-up mechanism then rotate at the same small increment, the heddle frames change position and the loom begins a new cycle.

These simultaneous movements are repeated over and over until the entire mesh cloth is woven.

The overall cost of architectural mesh is determined by several factors. This includes quantity, dimensions, and fabrication.

A good rule of thumb to follow is the smaller the quantity of mesh needed for a project, the higher the cost per square foot. At the same time, the higher the quantity of mesh needed for a project, the lower the cost.

To put it simply, mass production is where you see significant cost savings.

Sometimes pricing is quoted based on the initial drawings provided to the mesh supplier. If these drawings change during the buying process, the price per square foot is likely to change as well.

It should be noted that warehousing fees are applied if the mesh of a project is ready for delivery before the structure is finished or ready. These are separate fees and not included in the cost of the mesh itself.

Wire mesh cost is heavily influenced by the weight of the material. As the weight of the material increases, so does the cost.

That said, Mesh profiles that feature a higher percentage of open area will tend to be on the cheaper side of the spectrum.

Cable mesh is more expensive than wire mesh as it utilizes cables in the vertical direction. Despite the cables beginning relatively inexpensive, they must be spot-welded into place to prevent fraying.

Fine mesh profiles, while lighter than other mesh types, prove to be far more difficult to weave. Setting up a weaving loom for fine mesh panels is very time-consuming.

In turn, labor costs greatly increase.

Weaving special mesh profiles requires a tremendous amount of fabrication and labor. Taking this and the varying designs into consideration makes estimating the cost difficult.

As architectural mesh is a decorative material and provides no structural qualities, designers often look to reduce the cost of the mesh as much as possible to reallocate funds towards structural support.

This is where valued engineering comes into play.

Valued engineering is the process in which architectural designers eliminate certain elements of a structure to make the project more budget-friendly. Designers must take the fact the architectural mesh does provide weather protection, fall protection, and security into consideration.

With that, architectural mesh is a very customizable material. In fact, it can be fabricated to accommodate any project or budget.

Elements such as the wire diameter and mesh openings can be altered while still maintaining the aesthetic vision of the designer.

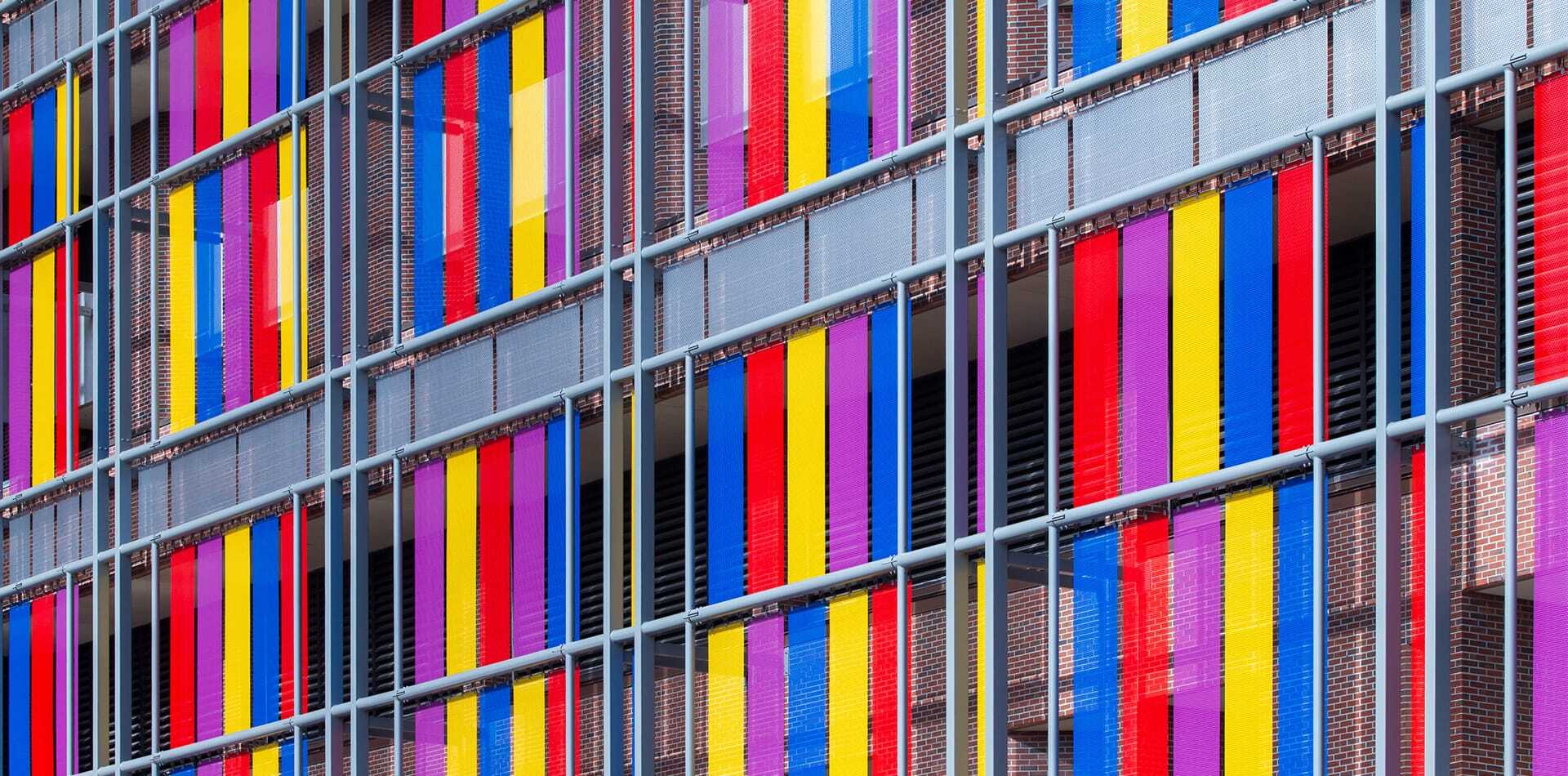

The most beneficial quality architectural mesh provides facades is the variety of mesh types. With so many mesh profiles to choose from, there is a solution that can provide everything you need to make your vision a reality.

Architectural mesh is also a great way to create natural ventilation. This is particularly useful when applying a façade to a parking structure that requires a certain amount of ventilation to follow city ordinances.

This is adjustable by customizing the openings of the mesh.

Sun protection is also achievable when architectural mesh gets used to construct exterior facades. By filtering the amount of sunlight that hits the structure, the temperature within the structure is more controlled.

As a result, expenses associated with air conditioning get reduced.

The versatility of architectural mesh allows it to serve as a retrofit. This means that if a structure already exists, mesh can get placed on top of it.

The life-cycle of architectural mesh is another key element to consider when selecting the material for an exterior façade. Architectural mesh is a durable material that lasts the lifetime of the structure with little to no maintenance required.

As it is weather-resistant, architectural mesh is suitable in most environments where the architect wants to create a heightened aesthetic.

Implementing an architectural mesh façade requires a significant amount of tension to prevent it from moving. That said, architectural mesh facades are limited to structures that are strong enough to handle the force created by the tensioning system.

The cost of architectural mesh is another element that can drive architects towards other design material, such as perforated plates.

When it comes to the cost of mesh material used for a project, there are several factors at play. Of these factors, fabrication tends to have the biggest impact.

This is particularly true for custom applications. In other words, the more customization needed the higher the cost.

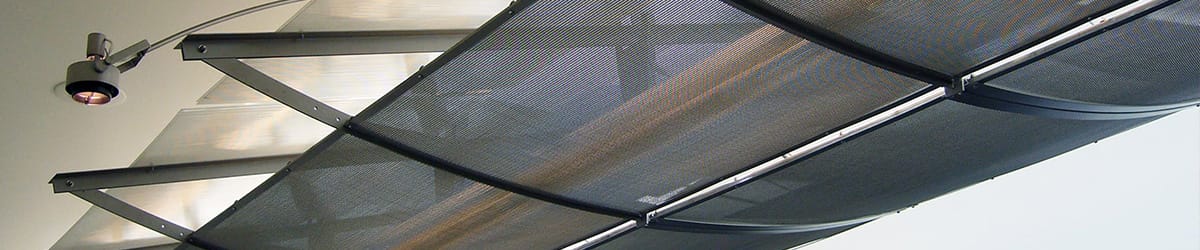

Architectural mesh, when applied to exterior canopies, provides a large amount of climate control. While architectural mesh provides a unique aesthetic to canopies, it also provides enough shade to reduce temperatures during summer while retaining heat during the winter.

While it provides excellent shading, architectural mesh canopies are a transparent product. This allows visitors to view the surrounding area from the inside out, providing a unique experience.

Architectural mesh canopies are perfect for sunny areas that don't see much rain.

The biggest drawback associated with architectural mesh canopies is that it doesn't block precipitation. As it is an open product, rain and snow can make its way through the openings in the mesh.

Architectural mesh infill panels can get customized to fit most railing systems. That said, if a railing system is already in place architectural mesh panels can cut to fit the grid.

DOKA-MON0 1591, for example, can be manipulated by hand to fit a railing system that's angled for a stairwell. This reduces the amount of excess material that is wasted.

Also, because it’s stainless steel, architectural mesh is durable. This is particularly beneficial when subjected to high volumes of traffic.

With that, exterior infill panels are ideal for entranceways and transportation structures.

The biggest drawback of an infill panel mesh system is that it can be expensive. As stainless steel mesh should not touch other alloy types, you will need to buy stainless steel framing.

Additionally, there are a lot of contractors that are not familiar with architectural mesh. If the contractor installing the mesh mishandles the mesh, it will get damaged and not portray the desired atmosphere.

Although architectural mesh is a stainless steel product, it is flexible. This allows it to get formed while maintaining the integrity of its structure.

This characteristic is particularly useful when forming sculptures around an existing structure. With that, architectural mesh can also be free-formed to protect sculptures from damage.

Free form architectural mesh is ideal for any area that needs an enhanced atmosphere and protection.

While stainless steel mesh is flexible, it is not as flexible as other materials, such as fabrics. That said, applications that call for material to take on a form with a tight radius can be difficult to achieve when working with architectural mesh.

In other words, you can only work within the flexibility of the mesh profile you choose.

Employing architectural mesh for ceiling applications will enhance the brightness of the room. Mesh allows light to shine through the mesh and disperse through the mesh panels.

This creates the ability to establish a unique sense of canister lighting. In turn, the number of light fixtures and electricity needed to light the area is reduced.

Custom cutouts that allow various building elements to drop through can also get added.

Architectural mesh is great for ceiling applications in areas, such as larger conference rooms or common areas.

However, it's applicable anywhere you are attempting to create a sense of flow.

Unfortunately, architectural mesh does not provide decorative sound absorption qualities. This is because it is an open product and the mesh openings allow sound to continue traveling throughout the area.

Instead, they enhance acoustics in the room, which we'll dive into later in this article.

Applying architectural mesh to the walls of a structure will enhance the appearance of the room. Instead of offering light diffraction, it adds a sense of texture to the walls.

Architectural mesh allows you to use the wall as a feature wall rather than having traditional paneling, siding, or drywall. That said, architectural mesh is ideal in large rooms and inside of elevator cabs where a sense of flow is desired.

As architectural mesh is a stainless steel product, visitor traffic is vital. If visitors are coming in contact with the mesh daily, the mesh will likely dent.

In other words, it is not the most sturdy solution when compared to other materials.

Also, because people are going to come into contact with it at some point, you run the risk of the mesh becoming dirtier quicker. This means you will have to use resources to clean it often.

When working with infill panels, the mesh can get cut to fit most infill panel systems. If a railing the ceiling grid is already in place, architectural mesh can cut to fit the grid.

If fine-mesh gets used, the mesh can wrap around an infill panel. This is ideal when an infill panel system splits into various directions.

Generally, infill panels get used for railing systems. Think stairways and walkways leading to the front door of a building.

When looking at railing systems you are going to want to use wire mesh rather than fine-mesh profiles. This is because fine mesh is too delicate for railing systems and will most likely tear when subjected to heavy amounts of traffic.

The biggest drawback of an infill panel mesh system is that it can become very expensive. That said, the price which you should expect to pay naturally depends on the application.

Handling can also be a major concern. If the contractor installing the mesh neglects to handle the mesh with care, it can get damaged and lose its luster.

Architectural mesh works wonders when trying to deflect and diffuse sound. Acoustic sound panels are applicable to both the ceilings and walls to redirect sound.

Mesh acoustic sound panels are ideal for any sort of performing arts center. But you can apply architectural mesh anywhere within a structure that needs acoustic enhancement.

The biggest drawback of using mesh to constrict acoustic sound panels is that it takes a lot of calculations to have full control of where the sound bounces to in the room. While some mesh may claim to have 0% open area, there is some airflow that makes its way through the mesh.

This along with factors, such as the gauge of wire and mesh opening sizes, makes calculating the level of acoustic value difficult.

As architectural mesh, especially fine mesh profiles, is very pliable, you can bend, twist, and form it around various objects. As mesh provides unique reflections value, visitors will receive a different feel every time they pass the architectural mesh system.

This is because the lights that are within the building and the room will be hitting and reflecting off the mesh at different angles.

With this in mind, architectural mesh is perfect for areas where you wish to incorporate sculptures or create a unique art piece.

The biggest concern integrating architectural mesh into a free form application is the fact that it cannot be returned to its natural form factor. This means that the contractor must be precise in placing the mesh in the exact location when working with the mesh.

Failure to properly place the mesh or handle it with care will result in creasing and crinkling that is irreversible and will take away from the feel of the mesh system.

There are a handful of components needed for wire mesh facades to maintain their architectural design qualities. Among these components are the substructure, clevis hardware, flat tension profile, pressure spring, and intermediate tube.

The substructure is the foundation of an architectural mesh system and is attached directly to the structure. Typically, the substructural frames are constructed out of galvanized steel and take on a profile that resembles the letter “L”.

The clevis hardware is the brackets placed at the top and bottom flat tension profiles. These brackets are designed to connect the mesh panels to the substructure frames.

The flat tension profiles are clamps placed at the top and bottom of each mesh panel. These clamps serve as a connecting medium that joins the mesh and clevis hardware.

The pressure springs serve as a failsafe for all tensioning applications and are attached at the bottom substructural framing. The springs are designed to provide the mesh panels just enough give to prevent damage while also maintaining its rigid aesthetic.

Lastly, the intermediate tubes are additional support beams laid horizontally behind the paneling of the mesh system. Each intermediate tube is methodically placed to prevent panel drifting when heavy winds are present.

Wire mesh systems are generally installed by a third-party contractor that has experience working with architectural mesh. A successful installation uses the following steps :

For more details surrounding the installation process, feel free to download our Installation and Maintenance Handbook.

When it comes to the cost of the installation of a wire mesh system, there are a handful of factors to consider. Labor costs will possibly drive the overall cost the most.

What are the labor laws? Are the workers union or non-union? These and several more labor-based questions should be asked.

The quantity of panels being installed will also greatly affect the cost. Naturally, the more mesh being integrated into a project the less the mesh will cost per square foot.

On average, you can spend $10 to $15 per square foot being installed.

When first introduced to architectural mesh, architects are generally concerned with the open area of the material. Several guidelines, such as parking structures needing 50% open area for ventilation purposes, come into play.

With that, mesh suppliers can assist you in the selection of a mesh profile that has an appropriate amount of open area while maintaining your vision.

NOTE: The more open area of the mesh the less amount of material will be used to construct each panel, resulting in a cheaper price tag.

Having said, the application will ultimately dictate the mesh profile you use.

To put this into perspective, tensioned panels should be constructed out of ridged mesh or cable mesh while specialty mesh can benefit interior non-tensioned systems.

Perforated plate, when looking just at the material, is in fact cheaper than architectural mesh. On average architectural mesh costs anywhere from $15 to $35 per square foot whereas perforated palate only costs $5-$10 per square foot.

With that, the cost of a fully installed wire mesh system is substantially cheaper than a perforated plate system. This difference in this cost comes down to the fact the perforated plate systems require intricate framing.

The downfall of these framing systems is that they require more material and labor than architectural mesh mounting.

Architectural mesh is a great design solution as it can be tensioned over the height of the project. However, adequate substructures must be put in place to absorb the significant loads the mesh creates (1400-1800 lbs per linear ft.).

Substructure frames are generally hot-dipped galvanized 6 x 6 x ½” L profiles.

Failure to integrate substantial substructure can result in the mesh system damaging to the building.

There is no standardization of architectural mesh specifications. In fact, the only aspect that can be considered standardized are the patterns of a specific weave type.

Elements such as the dimensions, quantities, and alloy are all customized based on the drawings you submit. This also means architectural mesh panels are made-to-order and typically not stocked.

It should be taken into consideration that lead times for architectural mesh are longer than other materials that are less custom, taking around 4 to 16 weeks to arrive.

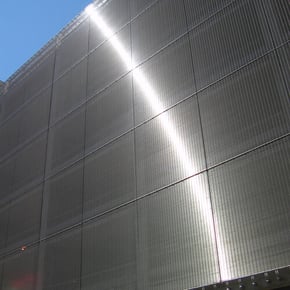

Architectural mesh’s visual qualities can be very dynamic, changing based on the weather and time of day.

When in direct sunlight, it glistens and appears opaque. That said, on days of heavy overcast, the mesh openings of the panels become visible.

When nightfall arrives, each panel becomes transparent when backlit from the lighting of the garage.

When stainless steel architectural mesh is painted, automotive-grade paint including a primer, bottom coat, and topcoat is applied. This leaves you with a thorough level of adhesion throughout the painted mesh panels.

Automotive-grade paint is also known for its elasticity. This means the paint will not chip or crack during shipment.

That said, if unwanted graffiti is applied to your architectural mesh system, it will not adhere and can power washed away with ease.

The buying process is initiated when the customer reaches out to our team and requests a quote. Once processed, you will receive the quote at which you will either accept or deny it.

If accepted, you will need to submit a purchase order for entry into the supplier's computer system. It’s at this time that the customer and supplier agree upon payment terms.

Once terms of payment are settled, the supplier usually requests finished drawings and renderings so shop drawings can be developed. The shop drawings will show the project reverse engineered with wire mesh panels.

You will either sign off on the shop drawings or submit redline revisions. Redline revisions are best desired as major changes customers make to the developed shop drawings.

Typically, we allow customers to request two red line revisions. If more than two are requested, additional fees may be applied.

NOTE: A licensed Professional Engineer (P.E.) must sometimes be present when approving shop drawings. The mesh supplier can recommend a reliable P.E. if needed.

After all, drawings are approved and finalized, mesh production and associated lead time begin. Fabrication typically accounts for 8 to 10 weeks with delivery (ocean or air-freight) accounting for 4 to 6 weeks.

Your architectural mesh/system will arrive in carrying containers designed to protect the integrity of the mesh. Inside the container, you will find everything needed to complete the project in its entirety.

Installation can then begin and, in a few weeks, your architectural mesh system will be complete.

Our primary goal is to make the buying process easy and seamless. With that, there are three methods you can use to request a quote and begin your architectural mesh journey:

To ensure a timely quoting process, you will need to have information about several elements of the project when reaching out. This includes:

Architectural mesh is one of the most unique design materials on the market, providing structures will a one-of-a-kind aesthetic. Whether you utilize wire mesh, cable mesh, fine mesh, or specialty mesh each wire mesh system has the ability to provide sun protection, branding opportunities, and fall protection.

With an average price range of $15 to $30, architectural mesh can be customized to accommodate any budget while capturing the vision of the architect.

As most architectural mesh systems are constructed out of stainless steel, there is virtually no maintenance needed other than occasional power washing when subjected to graffiti. Best of all, every architectural mesh system is designed to last the lifetime of the structure making it the ultimate architectural design solution.